There was a time when artificial intelligence (AI) was the stuff of science fiction writers. Many readers around the world, including me as a young boy, were tantalized by the possibility of a machine that could someday simulate—or even achieve—consciousness. Some people dreamily imagined a world in which intelligent robots did most of the work on earth and gave rise to an ethical source of cheap labor and a utopia for humankind. Others feared the sentient machines could become hostile, with something like a mind or “being” emerging from mere circuitry, metal, and synthetic skin. Regardless, scientists, engineers, writers, and readers alike understood that the rise of AI would change everything. Decades later, it has.

But what does it mean for supply chain management?

AI Has Brought About Dramatic Changes

AI is now used daily all over the world, thankfully without the dire consequences—or utopian outcomes—envisioned by some of its pioneers. Instead, we have useful, practical instances of artificial intelligence, such as smartphone applications, fraud detection, self-driving vehicles, and more. The numerous tangible uses for AI have transformed the business and technology landscape in a short time and will continue to expand. In fact, in a recent press release, IDC estimated that the market for AI hardware, software, and services will expand more than 16% in 2021, reaching over $327 billion. That estimate grew to over $500 billion by 2024.

Everyone Wants a Piece of the AI Pie

With a seemingly endless list of new use cases, businesses are busy putting AI to work to make operations more efficient, reduce manual effort through automation, and leverage AI’s enormous analytical power to create new revenue streams. Bigger corporate budgets for AI have led to a flood of new technology vendors rushing to get a piece of the AI pie. Everyone from small providers of niche solutions to multinational software vendors are clamoring to be included—whether they offer true artificial intelligence or not. Marketing materials are being published, email campaigns executed, and flashy presentations given to woo crucial decision-makers. Some vendors are even beginning to use the “.ai” domain extension in their website addresses to signify their specialization in AI, though it actually just signifies the Caribbean country of Anguilla.

This frenzied environment surrounding AI creates significant confusion, making it hard for decision-makers to understand the underlying technology well enough to see through the hype. At its core, AI is a technology involving advanced mathematics and computer programming. As such, understanding it can be challenging even if all the concepts and terms were defined exactly and used consistently by vendors. Spoiler alert: they are not. The fact that even the term “AI” is used to refer to different things, not all of which involve artificial intelligence at all, compounds the challenge.

AI Can Be Transformative for Supply Chain Management

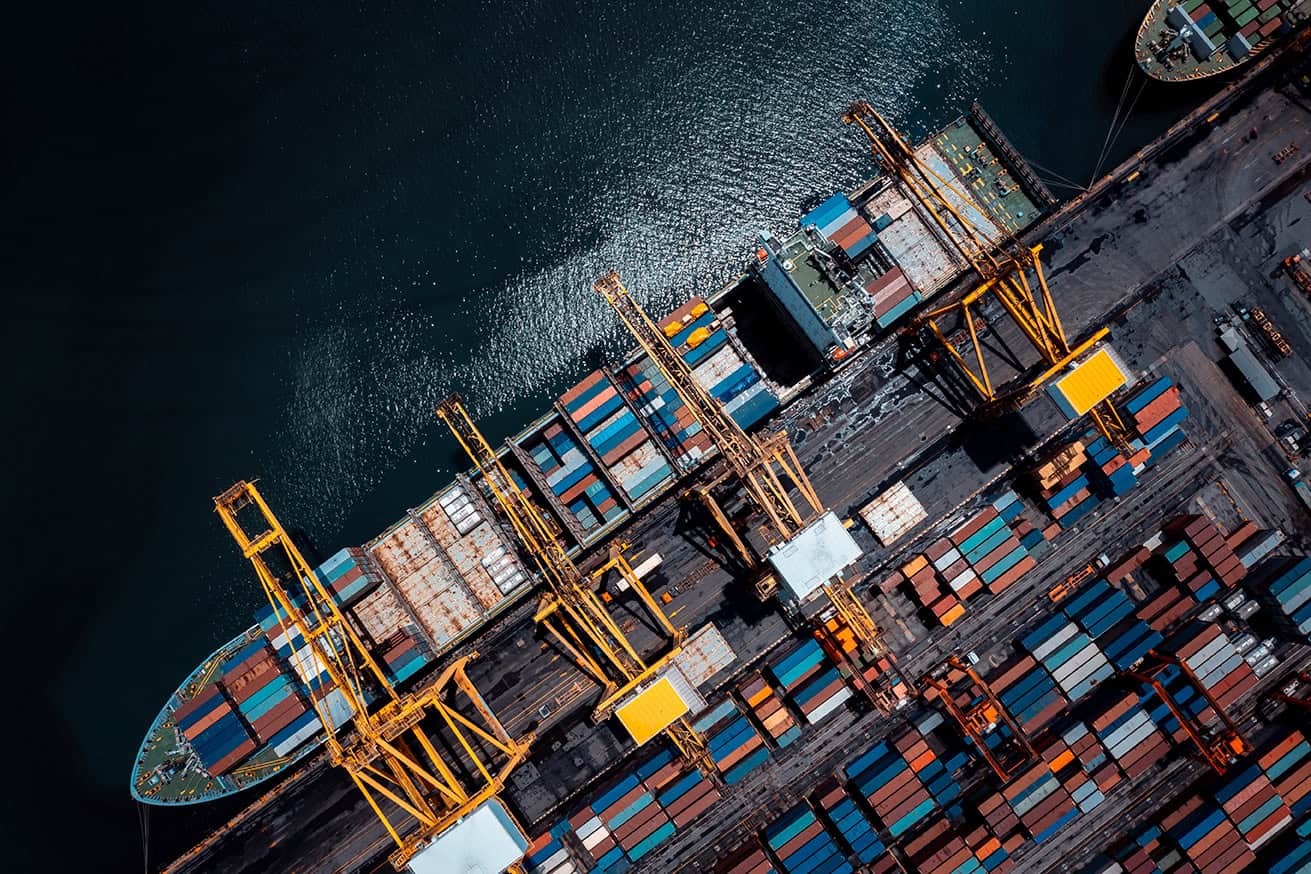

Of all the functional areas of a business where AI investments can yield high returns, supply chain stands out. Exceedingly complex, this mission-critical part of every business is driven by data and communication flowing upstream and downstream to and from the company. A single finished product can have tens of thousands of components sourced from many regions and many suppliers. It may have been manufactured in one place, then carried by third-party logistics (3PL) providers across many borders and jurisdictions involving various regulatory obligations and customs duty considerations, only to then be stored in warehouses with differing documentation and tax requirements. The product may finally be sold through channel partners around the world under contracts with diverse and specific clauses, the minute details of which must be meticulously tracked.

Does that summary seem complicated? Most business leaders would recognize that even those steps are drastically oversimplified compared to the reality of running today’s supply chains. In an era in which each of these supply chain events is supposed to happen “just in time,” the potential value of AI to help orchestrate processes and synchronize all stakeholders is clear. The supply chain is simply too complex and time-sensitive for true just-in-time operations to be managed manually. To complicate things further for decision-makers, gathering and analyzing data to optimize future decisions takes even more sophisticated capabilities compared to merely executing a previously specified supply chain plan.

Specific Criteria: Define the Right AI for Supply Chain

What if there were an easy-to-read guide that explains basic AI concepts and shows how the technology works specifically in the supply chain? What if there were a series of incisive, business-oriented questions for leaders to ask as they evaluate AI vendors? That’s what technology experts at e2open recently put together.

The Artificial Intelligence Buyer’s Guide takes the mystery out of AI:

- Walks you through the little-known secrets surrounding AI

- Breaks down the technical terms used by the experts and puts them into business language with a focus on value

- Offers real-world examples of AI being used to address challenges and create new opportunities within the supply chain

- Suggests many practical buyer’s tips that enable decision-makers to open the black box of AI and look inside with confidence and understanding

In a future blog post, I’ll be unpacking more of AI’s key concepts—especially how AI relates to data and the fundamental question of what constitutes AI in the first place. In the meantime, I hope you’ll explore the paper yourself to cut through the hype and better understand how you can make AI work in your supply chain.

More from e2open

White Paper

Artificial Intelligence Buyer’s Guide: Cutting Through Marketing Hype to Drive ROI

Access the White Paper