Supply chains have followed the same basic playbook for decades — and for a long time, that was enough. Companies made small process updates when markets shifted, but the core operating model stayed the same.

Today, everything is different.

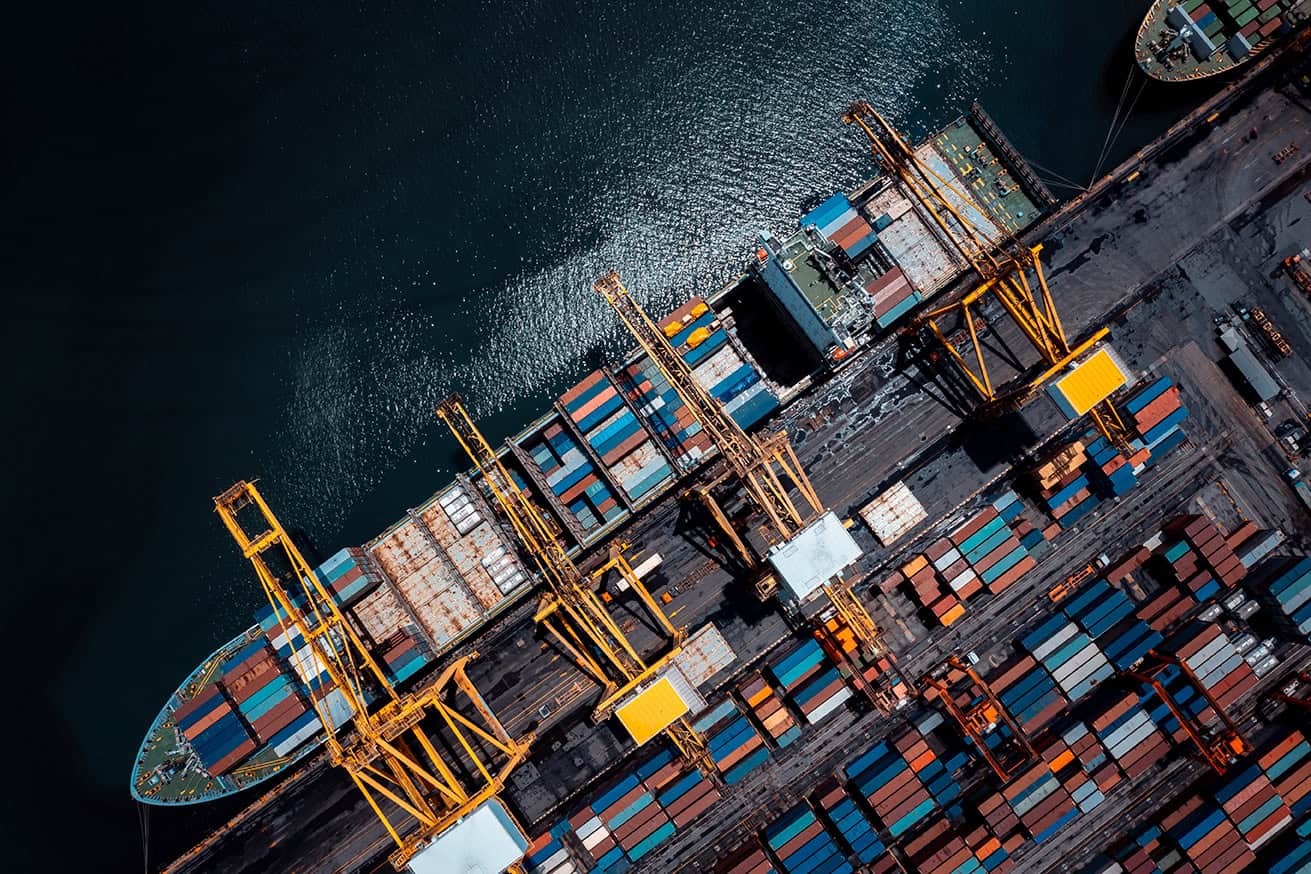

Modern supply chains are global, interconnected and under pressure to move faster than ever. Companies depend on a wide web of suppliers, manufacturers, logistics providers, distributors and service partners to design, build, ship, sell and support their products. This extended model delivers major advantages — lower costs, access to specialized talent and greater economies of scale. But it also creates visibility gaps, added risk and higher operational complexity.

The challenge: these partners are more interdependent and time‑sensitive than ever. To regain visibility and control across your end‑to‑end supply chain, you need real-time data flowing from every upstream and downstream partner, regardless of tier. You also need the ability to send updates and decisions back out just as quickly.

The limits of traditional connectivity

Most companies rely on enterprise resource planning (ERP) systems to manage their internal business. While ERPs provide valuable insight inside the four walls, they offer little visibility beyond them. To connect with external trading partners, many organizations still use point‑to‑point B2B connections.

The problem? Point‑to‑point connectivity is expensive to maintain, slow to deploy, and difficult to scale. It creates an incomplete, single‑tier view of the supply chain — which means limited traceability, greater blind spots and more surprises. You can’t truly control or optimize a global supply chain when you can only see a fraction of it.

So what’s the better approach?

E2open delivers a new way to connect your supply chain

It’s time to replace outdated point‑to‑point connections with an intelligent, cloud-based trading partner network. A modern network connects all internal teams and external partners on one operating platform. With this foundation, you can exchange information securely, collaborate in real-time and make faster, more confident decisions across your entire supply chain.

Why does this matter?

A field‑proven supply chain network helps eliminate blind spots by connecting every function, tier and ecosystem. It provides access to decision‑grade data that fuels upstream and downstream applications, plus AI and prescriptive analytics — all on a single platform designed for end‑to‑end supply chain performance.

What to look for in a modern trading partner network

To get the most value from your supply chain network, look for these core capabilities:

Integrated data model

A canonical-based integrated data model (IDM) normalizes and enriches data from multiple enterprises. This creates a consistent, decision‑ready view of the business and builds a digital twin of your physical supply chain.

Reusable connections

A “connect once, reuse everywhere” model speeds time-to-value. Multi‑tenant connectivity makes it easy to onboard new partners and eliminate redundant work.

Ecosystem-wide support

Your network should include partners from all four essential ecosystems — downstream channel partners, upstream supply partners, logistics providers and global trade partners. One platform supporting all four ensures every process has the data it needs.

Rapid onboarding

The network must support fast, efficient onboarding for suppliers, customers and trading partners. This includes large-scale rollout programs and the ability to manage them without slowing your business.

Flexible connectivity

Partners should be able to connect using standard industry protocols and payloads, including REST/JSON APIs, XML and EDI. Web portals enable manual data exchange when needed, and email-based options support partners with limited technical capabilities. A true “come-as-you-are” model meets every partner where they are.

Certified ERP integration

You should be able to connect internal systems — like ERPs and other systems of record — through certified adapters and end‑to‑end integration capabilities. This reduces project risk and accelerates deployment.

Enterprise-grade scalability

Choose a network designed for high performance, proven uptime and disaster recovery capabilities. A scalable platform grows with your business as you add more partners and expand globally.

The bottom line: A network unlocks the full power of your supply chain

A global supply chain network makes it possible to collaborate securely and confidently with every trading partner in real-time. When your entire end‑to‑end supply chain shares trusted, decision‑grade data, your business can act faster, reduce risk and uncover new opportunities.

The result? Better demand management. Stronger supply assurance. More reliable logistics execution. Smoother cross-border trade. And the ability to take control of your end‑to‑end operations with greater visibility than ever before.