Every company in the world operates as part of an ecosystem of interdependent entities:

- multiple tiers of distribution partners and possibly retailers to sell the company’s products,

- multiple tiers of suppliers, contract manufacturers, and packaging companies to enable making the company’s products and

- multiple logistics providers, 4PLs , freight forwarders, and agencies to handle moving raw materials, parts, and the company’s finished products across borders, customs, parties, manufacturing sites, distribution centers, and so on.

During business as usual, based on historical performance data, most companies can rely on traditional internal systems and processes to predict and plan their operations with a reasonable level of accuracy and execute their plans unperturbed to deliver corporate goals.

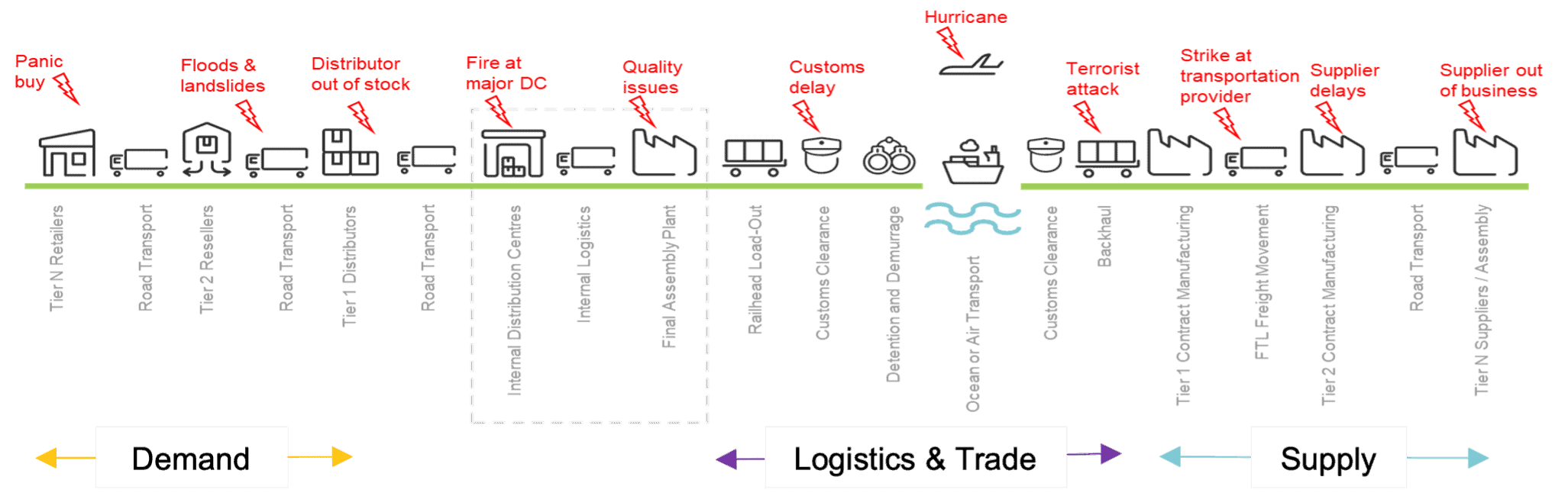

When unexpected events with the potential for disruption occur, companies must adapt their plans and their execution to maintain their ability to reach business objectives. Most disruptive events happen outside the enterprise four walls: suppliers going out of business, shortage of parts or labor, war, political unrest or natural calamities blocking access to resources, port or border congestion delaying transit, panic buy artificially inflating demand, etc.

Adapting plans and execution with agility demands near real-time access to data and connectivity to all the interdepended entities. That will enable the company to know immediately about any challenges and act collaboratively with the partners to address them.

Demand

Connectivity to all tiers of distribution and retail provides early visibility into any shifts in demand and the possibility to work with partners to

- capture rising demand opportunities,

- mitigate sluggish sales and

- ensure that customer expectations and promises around fulfillment are met through tactics such as partner referrals, buy-backs, cross-transfers, or reshaping demand.

Supply

Adding connectivity to the supply ecosystem enables timely alarm bells to any potential supply constraints and opens up opportunities to

- find alternative sources, whether alternative supplier capacity or alternative parts, or

- determine the potential for disruption of new orders and what negotiated terms will make those orders feasible.

Logistics & Trade

Further connectivity to logistics and trade ecosystems provides visibility and predictability of delivery and the ability to mitigate delays and shortages through

- re-routing goods in-transit,

- expediting shipments or

- from-store direct-parcel delivery.

All while maintaining any additional regulatory compliance requirements!

As the last few years have proven, business-as-usual is becoming a myth. Expect the unexpected is the new normal and maintaining performance, in some cases survival, is contingent on connectivity and collaboration with a vast multi-enterprise network of interdependent parties spanning demand, supply, logistics, and trade ecosystems. e2open provides the world’s largest network of interconnected partners across all four ecosystems. And the platform to put that network to work for you!

Check out the whitepaper Optimizing Omnichannel Performance in Supply Chain to Learn More about strategies to build resilience and contact e2open to understand how our network and connected platform can help you implement those strategies.