Environmental, social, and governance (ESG) issues have become a priority for executives. E2open’s multi-enterprise network brings you the data you need for reporting and real-time decision-making to meet your ESG goals.

Meet the ESG expectations of customers, regulators, and investors. Understand your impact and reduce greenhouse gas (GHG) emissions across Scopes 1, 2, and 3 while enhancing safeguards for social responsibility and governance throughout your end-to-end value chain.

Meet net-zero goals and strengthen social and governance practices

Rising importance of ESG for business and supply chain

Executives increasingly recognize the importance of ESG. Customers and investors demand it, governments require it, and a changing climate makes the consequences of inaction clearer each year. An organization’s ESG practices also affect employee recruiting and retention. For most companies, more than 90% of the ESG footprint is in the supply chain. That means the bulk of your footprint—including the impact of sourcing, manufacturing, transportation, and distribution—is likely outside your direct control or ability to easily measure.

Multi-enterprise challenge that Includes Scope 3 Emissions

Outsourcing compounds the problem by contributing heavily to Scope 3, which includes emissions from the sourcing, manufacture, transportation, end-use, and disposal of goods. By definition, this is a multi-enterprise challenge.

To track and report ESG impacts using relevant data, you require direct connections to your partners at every tier of supply, manufacturing, transportation, and distribution. Leveraging this data to reduce your footprint takes a supply chain operating platform that enables ESG-informed decision-making for the day-to-day activities of making, moving, and selling goods. E2open is ready with the connectivity, platform, and proven solutions that address your needs.

End-to-end ESG system of record for your supply chain

Comprehensive ESG programs involve working with all parts of the extended supply chain, including upstream suppliers, downstream distributors, and logistics partners at every step in between. End-to-end ESG is particularly elusive because the bulk of the footprint—especially Scope 3 GHG emissions—comes from outsourced third parties that are not under your direct control.

This makes tackling Scope 3 emissions inherently a multi-enterprise challenge. As such, any solution to track and help reduce end-to-end ESG impacts starts with a multi-enterprise platform at the core to connect your organization with its partners, capture information, and enable ESG-informed decisions while maintaining information security.

Many of the world’s biggest enterprises across various industries already use e2open’s network-based platform to successfully track cost and service metrics. The same core framework can also provide the foundation for an end-to-end ESG system of record (SOR) for your supply chain. The SOR could gather information from external partners and normalize it to make it decision-grade and useful for ESG reporting and decision-making. If you are interested in learning more about e2open’s ESG solutions, we look forward to connecting with you.

Demo Video

Check emissions footprint before booking freight

Discover how you can drive down your emissions footprint by identifying the lowest-carbon transport scenario before you book freight. Accurate GHG data helps you make smart tradeoffs.

Read the Blog

Time to go big on sustainability

Scope 3 emissions are quickly becoming standard in the executive lexicon. Find out why, what they include and how your supply chain presents a significant opportunity to reduce them.

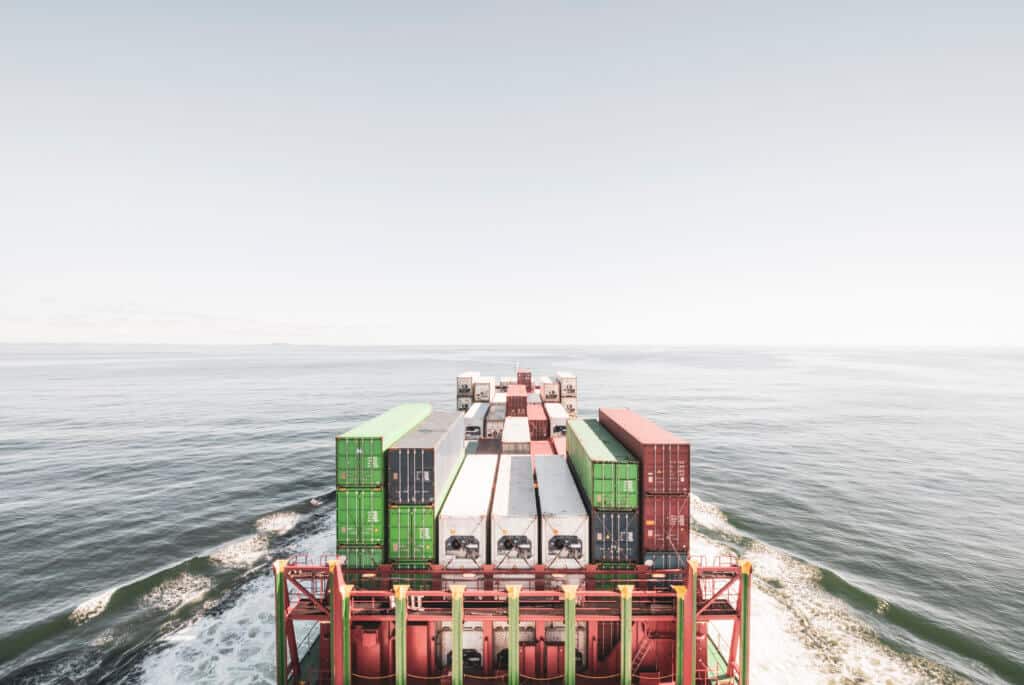

Transportation: lowering emissions and the cost of moving goods

Touching every supply chain ecosystem and stage of production, distribution, and returns, transportation has been estimated to account for about 25% of all GHG emissions. E2open’s accredited TMS lets you track the carbon footprint for shipments across all modes, legs, and regions. E2open empowers you in other ways too. By using artificial intelligence (AI) to create highly accurate forecasts, you can increase your confidence in customer demand and opt for slower transport modes with a lower carbon footprint. The next level is converting demand for finished goods into accurate transportation forecasts by mode and lane, then securing capacity with preferred carriers for the best rates and equipment with lower emissions. AI also helps you optimize loads to move goods with the fewest trips and match empty containers with nearby shipments.

Manufacturing: reducing resource consumption, waste, and costs

Manufacturing generates significant GHG footprints that are not easy to measure or mitigate, but e2open enables you to reduce the impact by weeding out inefficiencies and waste. Collaboration between designers and manufacturers helps prevent errors and miscommunication regarding product builds, including specification and procedure changes. As a result, constrained resources—both materials and production capacity—are less likely to be wasted. Visibility and quality checks during manufacturing help pinpoint defects so you can avoid spending time, money, and emissions on defective goods. Likewise, knowing if materials are banned or sensitive helps you maintain compliance and achieve social responsibility goals. If a recall occurs, track-and-trace capabilities help you reduce emissions and disposal footprints.

Inventory and fulfillment: repositioning stock as capital, carbon, and water

There are numerous ways to reduce inventory-related costs, waste and environmental footprints. E2open can help you optimize inventory to hold enough stock to meet service commitments at the lowest cost and avoid building too much, which leads to waste and the need for disposal. This is especially important for perishable goods. By leveraging the AI and real-time data in our solutions, you can improve forecasts to permanently reduce safety stock—and at the same time permanently lower the amount of capital, carbon and water use required to support your business and supply chain. Knowing what, where, and when customers will buy—made possible through increased forecast accuracy—helps you minimize emissions related to transshipments and extended storage while empowering you to better respond to changing market conditions.

Social responsibility and governance: enhancing protection for your brand and company

Protecting against instances of regulatory noncompliance and exposure to reputational risk is critical—and this is an e2open specialty. Trading partner management capabilities help you onboard only suppliers that meet your standards and run audits to verify that suppliers operate within the code of conduct with respect to human rights, working conditions, and other risk factors. Automated screenings of transaction partners help ensure that you don’t work with sanctioned parties. Robust trade compliance using the world’s largest database of global trade rules strengthens your governance, bolsters import and export compliance, and helps you use trade agreements to lower your total landed costs. A centralized data repository enables reliable reporting to confirm that social responsibility and governance targets are met.

Resources

Who Will Be the Supply Chain “Planner of the Future?”

E2open is helping redefine what it means to be a modern supply chain planner. In this video, Daniel Stidsen explores how the role is shifting—from reactive firefighting to strategic decision-making—powered by automation, better data, and more connected planning ecosystems.

Supply Chain Planning: Comparing Legacy Tools with a Connected Model

Let’s uncover why modern supply chains need a connected approach Supply chain planning is more challenging than ever. Teams are dealing with daily uncertainties, siloed tools, unpredictable market behavior, and disruptions across global networks. Traditional planning methods are anchored in rigid cycles and outdated data models, so they simply can’t keep pace. E2open Connected Planning is a modernized approach that brings together real‑time visibility, multi‑tier data, and AI‑powered supply chain intelligence to help teams make faster, more confident decisions. Download our infographic to see how connected planning transforms performance, agility, and resilience in the supply chain.

Decision-Centric Planning: A New Paradigm to Supply Chain Resilience and Agility

If there’s one thing you can count on in supply chain management, it’s change. Agility is essential in a world where disruptions jump seemingly out of nowhere and rattle the bones of supply chains from end-to-end. Sticking to old-school, static planning models is a recipe for getting left behind by a faster competitor. This white paper is your backstage pass to the future of supply chain planning. You’ll learn what decision-centric planning means, why it’s different from traditional planning, how e2open helps enable decision-centric planning, so it delivers clear business value. What is decision-centric supply chain planning? Decision-centric planning is a modern approach that empowers organizations to sense changes, assess impacts, and act in real-time. This method uses continuous monitoring and advanced analytics to drive faster, smarter decisions. The result? Supply chains that can adapt to disruption and seize new opportunities as they arise. How decision-centric planning differs from traditional […]

E2open Named a Leader in the IDC MarketScape: Worldwide Multi-Enterprise Supply Chain Commerce Network 2025

E2open is recognized as a leader in the IDC MarketScape: Worldwide Multi-Enterprise Supply Chain Commerce Network 2025 Vendor Assessment. Download the official IDC excerpt and see how modern multi-enterprise networks help businesses strengthen resilience, improve collaboration and visibility, and drive performance beyond your four walls. Why multi-enterprise supply chain networks matter Today’s supply chains depend on an intricate ecosystem of up and downstream partners. Studies—and experience—show most disruptions originate among these third-party partners. With a multi-enterprise supply chain network, companies can take an outside-in approach by collaborating across demand, supply, inventory, orders, transportation, and compliance in near real-time. Earlier signals mean faster response times. What you’ll learn in the IDC excerpt The IDC MarketScape: Worldwide Multi-Enterprise Supply Chain Commerce Network 2025 Vendor Assessment: Explains how businesses can use supply chain networks to address visibility and collaboration at scale Shares the capabilities and strategies of e2open Provides buyer guidance on how to choose a […]

Best Practices Across the Consumer High-Tech Supply Chain

Tired of running a supply chain you can’t fully see? High-tech consumer brands run on sprawling, multi-tier supply networks they often can’t see or control. Where every decision carries a price. Short product cycles, incomplete data, and poor visibility into sub-tier inventories trigger shortages, excess, and costly expedites. Add constraint-blind supply plans and informal allocation policies, and disruption quickly becomes wasted inventory and missed targets. This white paper reveals how leading high-tech brands can strengthen forecast accuracy, streamline supply and manufacturing collaboration, and make quick, smart decisions in highly volatile markets. Here’s what you’ll learn from this white paper: A clearer view of high-tech supply chain realities See how poor visibility and data in outsourced manufacturing amplifies risk. Proven methods to improve demand planning accuracy Boost early forecast accuracy with unified channel data and AI. Smarter ways to align suppliers around shared plans Reduce volatility and prevent the bullwhip effect […]

Enhancing NPI Forecast Accuracy with an AI-Powered Demand Forecast Solution

How one company streamlined the forecasting process for successful new product launches New product introductions (NPIs) need accurate demand forecasts. Why? Good forecasts help companies better manage inventory, reduce stockouts, and meet revenue targets. A leading global consumer packaged goods (CPG) company struggled with NPI forecasting, and consistently overestimated true demand. The company’s forecasting capabilities were in dire need of an overhaul. They partnered with e2open to transform their approach to demand forecasting by leveraging cutting-edge innovations like demand sensing and AI clustering.

Forecast Accuracy Why it Matters and How to Improve It

The hidden cost of “good enough” forecasting The uncomfortable truth is that many companies are measuring forecast accuracy at the wrong level. While your C-suite sees strong quarterly numbers, at the supply chain execution level where service and inventory happen, forecast accuracy is much lower. Why traditional forecasting is failing in today’s market Your forecasting challenges aren’t unique. According to Gartner research, forecast accuracy directly impacts critical service metrics across industries. Yet, some companies still rely on historical data to predict an increasingly unpredictable future. The problem compounds at every level: At the executive level Accuracy: 77% Used for production planning and materials purchasing Creates false confidence in forecasting abilities At the planning level Accuracy: 69% Used for inventory planning and production sequencing Misalignment starts to show At the execution level Accuracy: 50% or lower Where fulfillment, deployment, and logistics happen Where most service issues actually occur

Pressing the Accelerator on Supply Chain Collaboration

A global mining and construction vehicle manufacturer known for producing top-tier mining and construction equipment relies on a vast supply network to keep their machines running smoothly. With thousands of suppliers, factories, and dealers scattered worldwide, maintaining clear visibility and seamless supply chain collaboration is crucial, especially when managing interdependencies within different tiers to ensure a reliable flow of goods.

Just the Facts: Highlights from the e2open 2024 Forecasting and Inventory Benchmark Study

Building resilient supply chains for uncertain times What does it take to prepare for the unexpected? The e2open 2024 Forecasting and Inventory Benchmark Study analyzes five years of supply chain performance, uncovering lessons learned from the pandemic and actionable strategies to prepare for what’s ahead. In this fact sheet, the top three takeaways from the report are broken down for a snapshot look into: How the pandemic reshaped supply chain planning and forecasting, with two striking trends The hidden vulnerabilities and diminishing returns of traditional planning methods Proven strategies and benefits of using AI and inventory optimization, including reduced forecast error Explore how innovative approaches like AI-driven demand sensing and multi-echelon inventory optimization (MEIO) help businesses improve forecasting, reduce inventory, and gain a competitive edge during volatile times. Gain the insights. Gain the resilience. Lead the way. Download the fact sheet or submit the form below to receive the full […]

AI’s Role in Managing Supply Chain Disruptions: Supply Chain Performance in the Wake of the Pandemic

Can AI and real-time data be effective in a pandemic-scale disruption? The data says – yes! In this informative webinar, John Lash, GVP of Product Strategy, shares fact-based insights from e2open’s latest Forecasting and Inventory Benchmark Study. John goes beyond the numbers to provide actionable recommendations for how companies can use real-time demand data and AI to improve supply chain performance and manage future disruptions. You’ll discover: How AI helped supply chain leaders make better decisions and mitigate the impact of demand shocks and constrained supply before, during, and after the pandemic How the pandemic made doing business harder than ever Strategies adopted by global manufacturers in response Lessons learned to help you manage future disruptions – even on a global pandemic scale Speaker: John Lash GVP, Product Strategy e2open

Shadow Planning with a Digital Supply Chain Twin: Zebra’s Journey

Driving a high level of supply assurance requires a connected, streamlined approach with deep visibility into the multi-tier supply chain, enabled by collaboration with contract manufacturers and tier 1 and 2 suppliers. As the trusted brand for more than 80% of Fortune 500 companies for innovative technology solutions that digitize and automate workflows, Zebra understands the value of connected planning and supply to maintain customer satisfaction and a healthy bottom line. During this engaging on-demand webinar, you’ll learn about Zebra’s journey of building a digital supply chain twin and integrating a shadow planning process that lets the company monitor production in real-time, avoid potential disruptions, and ensure a more reliable flow of materials across the value chain. You will discover: The concept and practical application of shadow planning with a digital supply chain twin How to increase collaboration within the extended supply chain to drive supply assurance The […]

Orchestrating Supply Chain Success with Connected Planning

In today’s interconnected world, supply chain success is built on three crucial elements: visibility, analytics, and collaboration. In this webinar, experts from KPMG and e2open speak on the power of Connected Planning. You’ll learn how integration & collaboration within the extended supply chain, from suppliers and logistics providers to end customers, can lead to more efficiency, effectiveness, and responsiveness. Discover insights, market trends, and use cases and uncover the common pitfalls of isolated planning transformations – and how an end-to-end approach to planning can accelerate value realization. Speakers: Pablo Quintano Senior Director, Enterprise Solutions Consulting e2open Jeremy Xander Procurement & Supply Chain KPMG

Working in Concert: How Supply Chain Planning Software Streamlined a US Audio Company

Learn how a combination of supply planning and collaboration provides control over component inventory liabilities and supply assurance Founded in 2002, this American audio equipment manufacturer is known for its high-quality wireless, multi-room audio systems. Partnering with leading music services, this organization has made significant strides in the audio industry. Their supply chain utilizes outsourced contract manufacturers (CMs) and requires constant management to ensure seamless component availability.

Mastering S&OP Excellence: A Manufacturer’s Success Story

Discover how a matrixed manufacturer transformed its global operations with e2open A prominent €11 billion conglomerate in the global building and housing market faced operational challenges stemming from their rapid acquisition strategy. Collaborating with e2open, the company embarked on a transformational journey to modernize its sales and operations planning (S&OP) processes. They implemented e2open solutions for S&OP, demand planning, and multi-echelon inventory optimization, adopting a crawl–walk–run–fly approach with agile methodology. By focusing on data cleansing, human-centered change management, and local champions, the company successfully streamlined operations. Download the brief to learn how the company successfully implemented e2open solutions, achieving enhanced supply chain visibility, improved demand planning accuracy, and significant cost reductions. Contact e2open to discuss strategies for global S&OP optimization.

Candymaker Leverages Demand Sensing AI to Resolve Volatile Demand

Demand intelligence keeps sweets on the shelf This iconic candy and snacking brand struggled with cumbersome manual processes and zero visibility into changing demand patterns, leading to missed opportunities for taking timely, corrective measures. Thanks to Demand Sensing Artificial Intelligence (AI) solutions from e2open, they can now identify causal demand signals, automatically generate highly accurate daily forecasts, and preemptively adjust supply to keep their products on the shelf while reducing stockouts. Read the full story here and connect with e2open to discuss how our demand intelligence solutions can help your company optimize supply chain agility.

Customers

Testimonials

Air France® Industries KLM Engineering & Maintenance

Renault Group

VMware by Broadcom

Leschaco

Michelin

Jabil