Table of contents

- State of the consumer-packaged goods industry

- Consumer packaged goods industry experiences challenges with new complexities

- Rapidly changing consumer buying habits

- Accelerating the move to modern supply chains and digital technologies

- Complex issues call for a more connected CPG supply chain

- What if you had a connected supply chain?

- Predicting volatile consumer demand

- Fastest ‘time to insight’ with automated data access

- Less risk and new supply sources

- Improved supplier relations and reliability

- Visibility and control – internal and outsourced

- Logistics visibility through all-mile delivery

- Environmental, social and governance (ESG) readiness

- Why e2open?

- Network architecture

- The largest network of interconnected partners

- Key benefits

State of the consumer-packaged goods industry

Volatile consumer demand complicated by supply constraints

Can supply chains adapt as quickly as consumers change their buying preferences? As a result of years of ongoing disruptions, increased consumer focus on environmental, social, and governance (ESG), and today’s economic uncertainties, the need for supply chain resiliency is top of mind for all consumer-packaged goods companies. Resiliency offers the ability to predict demand, manage supply constraints, and gain visibility into outsourced production and logistics – all the way to last-mile delivery. Today’s supply chain management has a whole new set of complexities.

Consumer packaged goods industry experiences challenges with new complexities

Increasing volatility in demand patterns adds risk to customer service levels & loyalty

Supply constraints & risk require alternate sources & geographies

Margin erosion from supply chain complexities that bring increased costs

Agility to adapt business to deliver products via today’s multichannel models

Limited predictability of near- and longer-term demand and supply swings

Lack of visibility & control with increased outsourcing of manufacturing & logistics

Lack of readiness for ESG requirements and demands for social responsibility

Poor logistics visibility all the way to last mile impacting service and adding costs

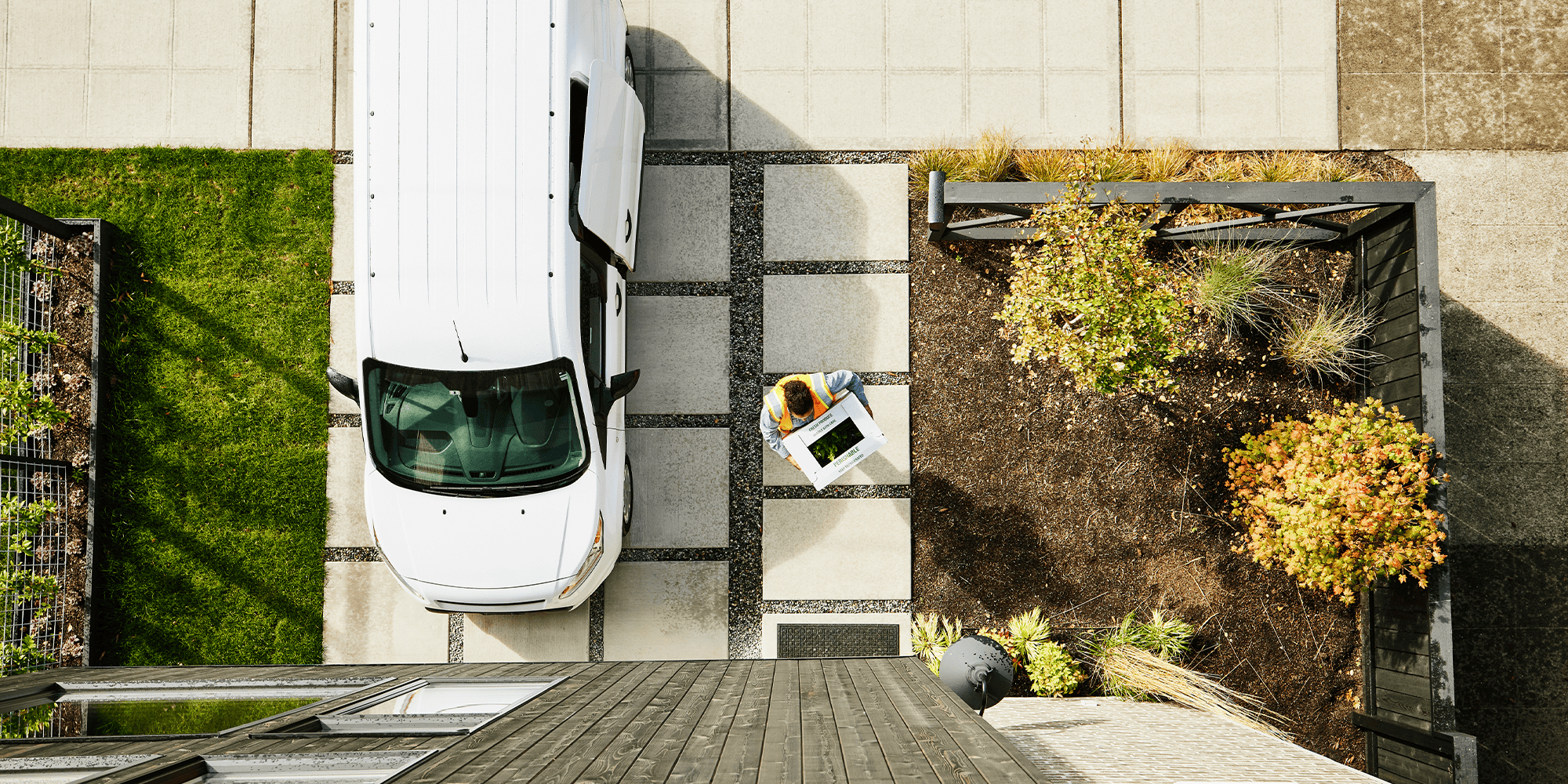

Rapidly changing consumer buying habits

As a result of ongoing global disruptions and economic concerns, the day-to-day buying habits of virtually everyone in the world change quickly and dramatically, putting a spotlight on the need for supply chain agility and resiliency. Resiliency means many things, such as supply assurance, predicting demand, visibility into logistics from start to all-mile delivery, and an effective strategy for navigating complex global trade policies and regulations. CPG companies have created new products and channels, such as direct-to-consumer, to adapt to the explosion of online shopping and take measures to ensure the availability of high-demand items.

Consumers are increasingly focused on health, quality, and social responsibility. Often their buying is influenced by product sourcing and tracing transparency, product personalization, and sustainable practices. Addressing consumer, investor, and regulatory focus on environmental, social, and governance (ESG) demands is today’s challenge which requires immediate attention.

Accelerating the move to modern supply chains and digital technologies

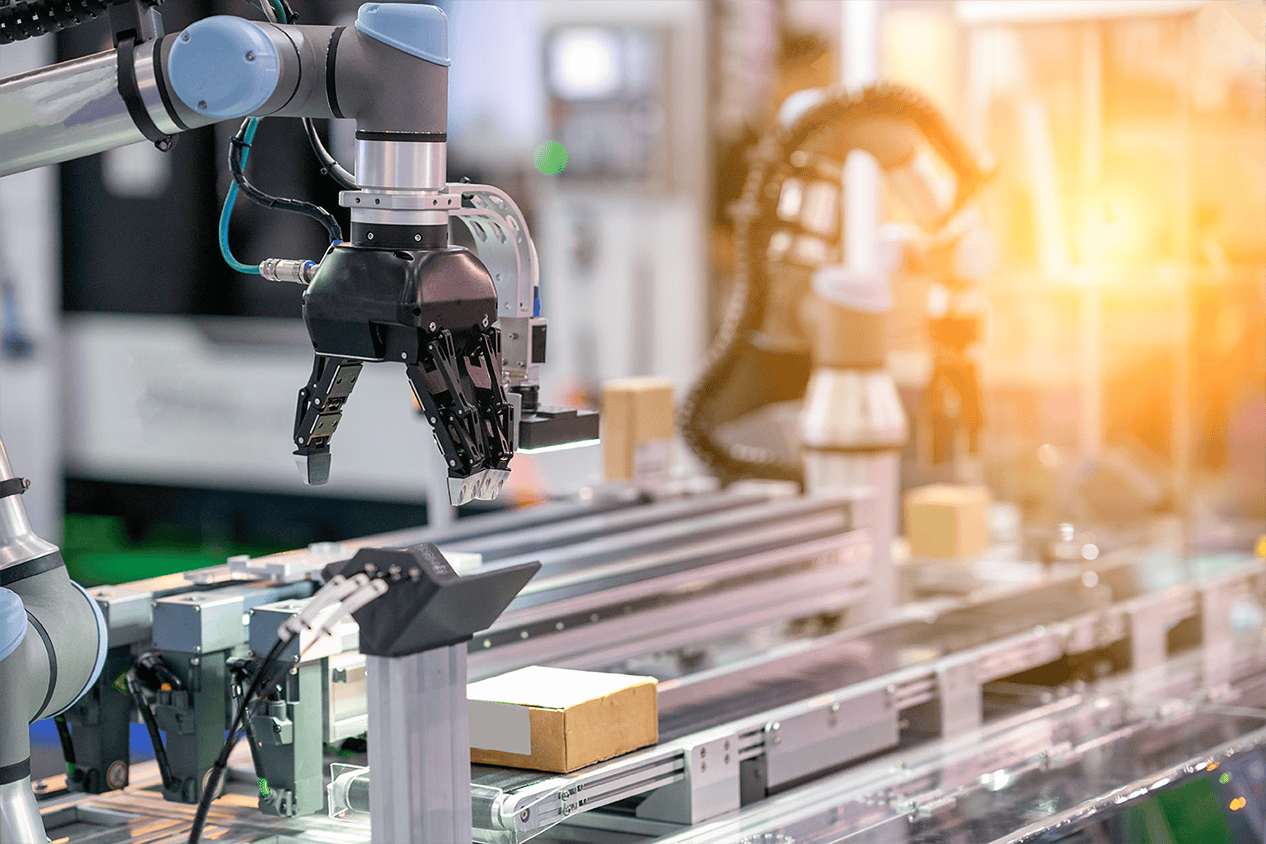

To compete, CPG companies are reassessing their core competencies and identifying partners — such as contract manufacturers and co-packers — for outsourcing at an increasing rate. With all the benefits of outsourcing comes the loss of visibility and control, yet this comes at a time when building resiliency requires more visibility and control, not less. Forward-thinking CPG companies are hitting the accelerator on their digital plans. Many leverage real time data and AI technology across all their planning and execution applications. It’s time to prepare for future disruptions and meet changing consumer expectations by optimizing your supply chain — end-to-end.

Complex issues call for a more connected CPG supply chain

Structural challenges of today’s supply chains |

|

|---|---|

| NOT integrated | Disconnected processes, systems, applications and data |

| Poor data | Late, inaccurate and incomplete data leading to indecision |

| Siloed decisions | Misaligned priorities leading to disconnected and uninformed decision-making |

| Reactive | A series of hasty decisions and delayed responses resulting in poor outcomes |

The modern supply chain |

|

|---|---|

| Integrated | Unified supply chain technology platform and interconnected partner network |

| Harmonized | Timely, accurate, and complete data enabling decision grade insight and information |

| Connected decisions | Real-time decision-making capabilities and automated responses |

| Proactive | Business transformation and a supply chain working together as one |

What if you had a connected supply chain?

Predicting volatile consumer demand

Is your forecast accuracy keeping pace with changing consumer demand?

When disruptions, market volatility, and shifting demand make forecasts unreliable, you know that traditional demand planning techniques aren’t keeping up. Along with fast-moving consumer preferences, CPGs deal with escalating product introductions and item proliferation, varying marketing programs for influencing consumers, and the impacts of omnichannel distribution. While demand planning typically generates a monthly, quarterly, or even 18-month forecast, near-term activities such as replenishment are usually planned daily. The traditional approach to bridging this gap is to use simple rule-of-thumb proration logic to convert monthly or weekly forecasts into the daily granularity required by distribution requirements planning. However, this conversion step yields a crude estimate of daily demand. It fails to consider other vital factors, such as the multitude of available signals or how orders in one period affect orders in subsequent periods. With e2open Demand Sensing, organizations use real-time data to produce accurate weekly or daily forecasts. The result is better replenishment decisions — every time.

Dramatically improve forecast accuracy with demand sensing to include the masses of real-time demand signals available across the supply chain and automation and AI technology to make this data useful.

In our world where point of sale (POS) data, promotions, weather, and even social influencers can impact demand overnight, imagine working with daily forecasts that reflect current market realities based on real time data, automation, and artificial intelligence (AI). Add in the latest data on open orders, shipments, and consumption, as well as customer and channel inventory to develop an even clearer picture of demand. When you access and combine these types of demand signals, you can predict near-term demand with superior forecast accuracy – helping CPG companies detect demand shifts affecting customer orders. Leading companies that “sense” demand using e2open typically improve forecast accuracy by 30 to 40%.

Fastest ‘time to insight’ with automated data access

Are your data analysts gathering data or improving your business planning daily with data rapidly delivered to them?

Insight into consumer demand and a quick response to any changes are critical to CPG companies, yet the ever-increasing variety, velocity, and volume of available data do not make these tasks easy. Today, POS data from retailers, brokers, and merchandisers, as well as data from merchandisers, as well as data from other sources — planograms, sentiment data, demographics, weather data, etc. — are readily available. The information is

difficult to combine and use because the same metric varies across sources, data formats, and frequencies – together, these challenges require advanced technology. Teams of analysts are no longer managing the growing sources of demand data to derive insights manually. These processes are now driven by demand analytics and embedded application intelligence that automate the process and enable analysts to use their time to gain rapid insights to identify strategic opportunities.

Respond to market forces faster to drive higher revenues, improve margins, and launch products and promotions successfully.

Demand Signal Management captures, harmonizes, and synchronizes your demand data from retailer data feeds, as well as from other sources, such as operational data, planograms, syndicated data, weather systems, and much more. By applying pre-emptive analytics, e2open makes sense of this disparate data – identifying potential trends, highlighting metrics, and generating insights that enable you to take productive action. As CPG companies gather the correct demand data, and perform analytics to gain meaningful insights, they can translate those insights into action. But analytics overlays are not enough. With e2open, this harmonized, synchronized data has a streamlined integration into the demand sensing application for complete automation to improve demand visibility, product availability, and supply chain responsiveness.

Less risk and new supply sources

How quickly and effectively can you grow your supply chain to expand your supply sources to minimize risk or near-shore?

The past few years have pushed CPG companies to face up to the vulnerabilities in their supply chains. CPGs seek new sources of supply to diversify the geographic location of suppliers, support new product innovation, and add backup supply sources to minimize risk from disruptions. These trading partnerships are complex, and onboarding suppliers often involves a myriad of manual processes. CPG supply chains can involve hundreds or thousands of suppliers across time zones and geographies. Each is an essential part of the smooth flow of goods, and careful management of the ongoing documentation for each is crucial to success. Onboarding new partners often involve extensive back-and-forth through phone calls and emails. Much of this communication — including key milestones — is decentralized, making it difficult for CPG companies to track and assess progress.

Rapidly onboard new suppliers onto a single automated platform to meet risk reduction goals.

Mitigate risk and increase speed-to-market by automating and streamlining the complex onboarding process, communication, and oversight of trading

partners. CPG companies can gain flexibility and simplified management of trading partners on a single platform, achieving complete visibility upstream and downstream. It’s one thing to identify a new source of supply and yet another to gain the advantage of the new partnership quickly. When new trading partners come on board, companies must also ensure all parties are aligned by clearly communicating brand standards and internal procedures. Providing user-friendly templates and training materials to ramp up quickly creates a great start to the partnership. This speed-to-market and ease-of-use make the process more efficient for CPG companies and partners, creating shared value and helping lay the foundation for effective long-term collaboration.

Improved supplier relations and reliability

Can you foster supplier relations to help ensure a sustained, reliable supply source?

When supply constraints plague every CPG company, sustaining your supply sources becomes mission critical. Suppliers of raw materials, components, and packaging often work not only with your company but also with competitors. When it comes to your orders, you want a consistent supply source. Bringing new and existing suppliers onto a connected supply chain can minimize challenges for CPGs and their suppliers alike, including improvements in supplier on-time deliveries

through order error reduction, reduction in inventory – and associated costs – due to right-sizing inventory across all tiers, and enhanced productivity through automation.

Interact with your suppliers through automation and connectivity to develop long term, sustained supplier relationships.

Purchase orders, inventory, and forecast collaboration on a connected supply chain allows all trading partners to collaborate and communicate to share data that promotes an environment where all parties participate in solving supply issues together. Inventory shortages that may impact purchase orders and customer commitments can be resolved by jointly planning changes to meet business goals. Simply put, communicating across a connected supply network makes it easier for suppliers to do business with your brand. But suppliers come with varying IT capabilities, so you need to offer a means of connecting and communicating with both major suppliers and long-tail suppliers. E2open’s come-as-you-are integration strategy meets partners at their maturity level, enabling companies to digitally transact with all their suppliers regardless of volume or technical capability. Effective collaboration helps you develop trust and confidence, leverage economies of scale, and create a more agile, responsive, and efficient supply network. A supplier collaboration platform with a great user experience will enhance your relationships with suppliers to help attract and retain partners – building your company’s supply assurance.

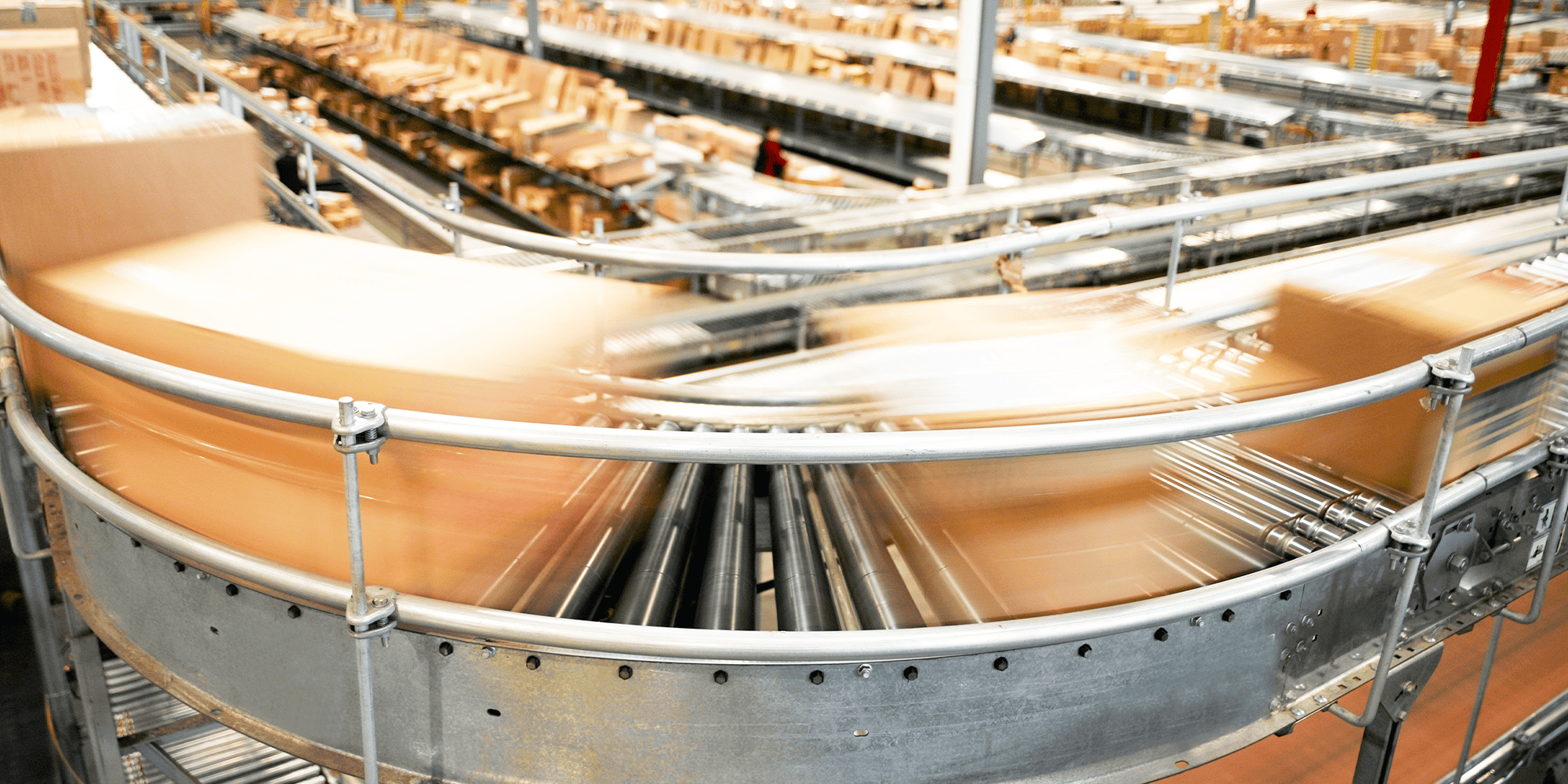

Visibility and control – internal and outsourced

Are you experiencing more benefits or challenges with your company’s outsourcing?

Strategically outsourcing manufacturing production and packaging is imperative for most CPG companies to improve time-to-market, gain agility, access specialized technology, focus on core competencies, and reduce costs. However, the increased complexity from a broader ecosystem of partners brings significant challenges to managing quality and operational control – often negating financial benefits. When quality issues arise, early detection becomes crucial. A brand owner’s ability to quickly determine the root cause at any production stage or node, track all affected products and efficiently conduct a recall is strategic. The sooner the issue is detected, the less impact on the brand, cost, and, most importantly, consumer safety. Having granular-level visibility into and control over all production steps, whether internal or outsourced, helps ensure quality and minimize the cost impact on the company when issues occur.

Gain visibility and orchestrate data-driven decisions across internal and external production.

The benefits of outsourcing are achievable on a connected supply chain when a holistic view of production performance extends across internal and external facilities. The same control is required whether it is a parent company plant or one from expansion with merger and acquisitions. It

requires automation of real-time information exchanges with and among partners to increase efficiencies, improve quality, adhere to consistent standards, and understand supply availability to experience the benefits. By collaborating throughout the process, companies can accurately transfer manufacturing, test, and quality instructions to all production facilities and receive manufacturing quality metrics to proactively identify non-conformances in processes and quickly address variances before they become supply chain issues. Manufacturing visibility and collaboration contribute to a more profitable and efficient business. E2open helps CPG companies connect their supply chain and gain complete end-to-end visibility and control. Their strategic outsourcing is poised to bring the expected benefits, and CPGs can successfully produce and deliver products to global markets at the right place and time.

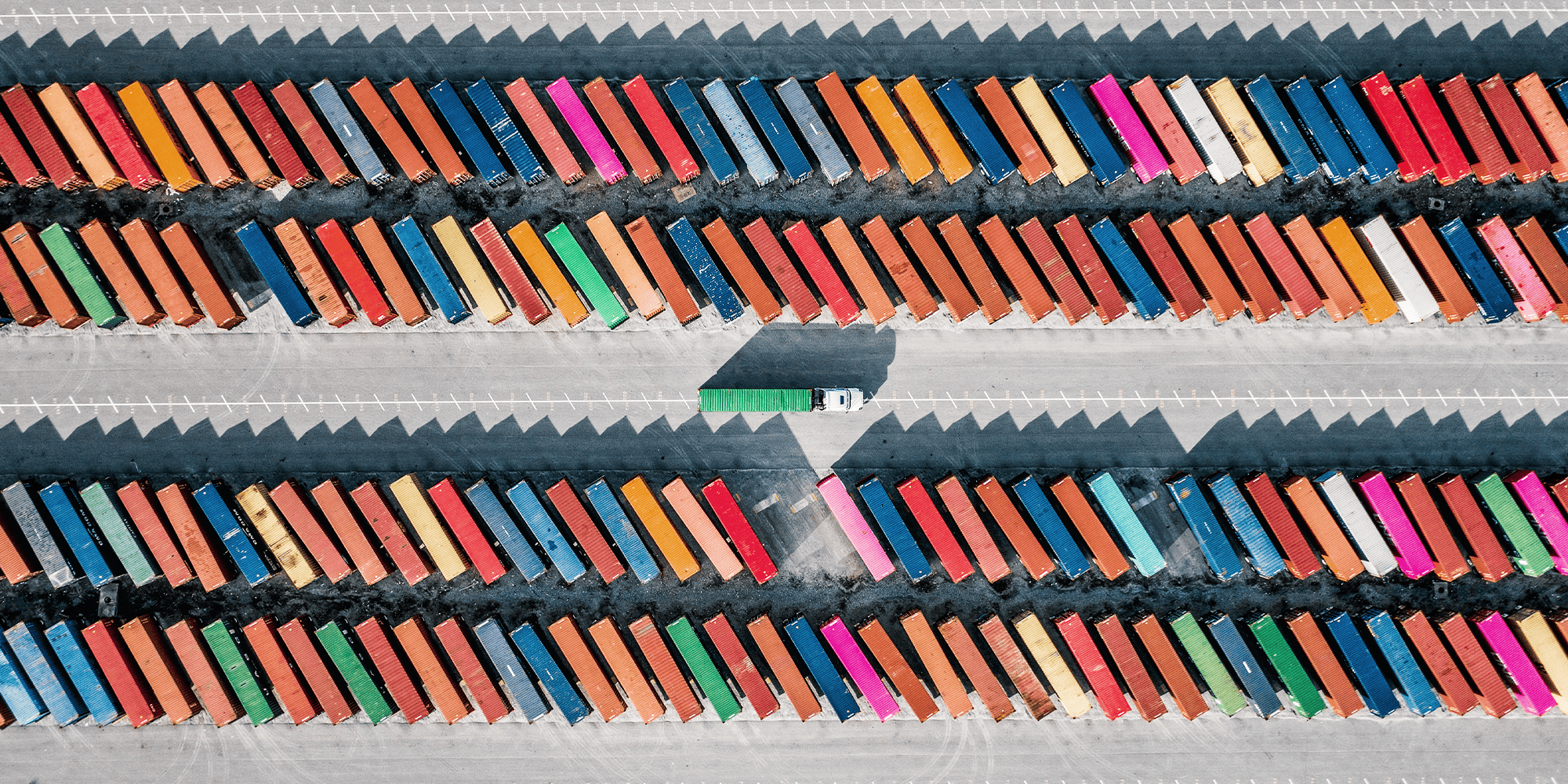

Logistics visibility through all-mile delivery

Do you have the logistics visibility and compliance needed throughout the production process and delivery to selling partners and consumers?

Changing consumer demand, ongoing disruptions, supply constraints, and economic uncertainty have CPG companies adapting logistics needed to get products through production of products – requiring varying transport modes o deliver finished goods to the right channel or directly to customers. New complexities in today’s omnichannel environment hinder companies from delivering on time and in-full. Consider further that organizations cannot manage what they cannot see. Modern supply chains are a system, and each component depends upon others. Managing the whole requires granular visibility into all the parts. Without this real-time visibility, leaders cannot identify potential supply chain disruptions, understand how they affect

downstream operations, or efficiently execute remedial actions. The results are missed hand-offs and a frantic scramble to make alternate plans, reassure dissatisfied customers, and avoid costly penalties and fees.

Control the end-to-end transport of goods on the move with 20/20 vision and make intelligent logistics decisions to minimize impact of delays.

Consistently know the real-time status – with extreme accuracy – of outbound and inbound goods on the move from 1st move in production to final delivery for all shipment modes, legs, and regions, including estimated times of arrival (ETAs). Along with visibility into the exact location of shipments, you can confirm the contents of each container and know if that cargo is critical to time-sensitive production schedules or less-urgently destined for safety stock. All stakeholders gain better insight to help make better decisions that mitigate the impact of disruptions that occur along the way. Eliminate penalties caused by missing on-time, in full (OTIF) commitments and raise the overall customer service levels you provide to build on your brand by taking control using e2open’s logistics platform. Effective parcel shipping, and all types of last-mile fulfillment, have become competitive advantages for CPG companies. Due to complex regulations, tariffs, and documentation requirements, cross border commerce was among the most intimidating aspects of parcel shipments. With e2open’s visibility platform, the journey of your parcel shipments is streamlined from label to delivery – locally or across borders – while reducing costs, fully documenting for compliance, and improving the customer experience. Logistics is a highly complex part of your supply chain. From transportation forecasting to booking execution and end-to-end visibility, e2open is uniquely positioned to provide this level of end-to-end supply chain planning, execution, and insight to identify issues early and provide you the intelligence to understand the impact and tools to orchestrate the optimal resolution.

Environmental, social and governance (ESG) readiness

Do you have a plan to meet consumer expectations, avoid fines for regulatory noncompliance, minimize your environmental impact, and maintain an ethical supply chain?

For most CPG companies, it is estimated that more than 90% of the ESG footprint is in the supply chain, which means the bulk of your footprint – including sourcing, manufacturing, transportation, and distribution – is likely outside your direct control or ability to measure easily. Outsourcing compounds the problem by contributing to Scope 3 greenhouse gas (GHG) emissions, which includes your footprint from the sourcing, manufacture, transportation, end-use, and disposal of goods. By definition, this is a multi-enterprise challenge. Understanding your ESG impact takes data – and lots of it – from every corner of the supply chain, establishing direct connections to your multi-tier partners. The connected supply chain and its applications discussed above all play into your task of mitigating ESG risks. By using AI to create highly accurate forecasts, you can increase your confidence in consumer demand, allowing you to optimize inventory – permanently reducing safety stocks – so you can produce less, keep service levels high, and lower the amount of capital, carbon, and water use to support your business. Manufacturing generates a significant GHG footprint that is difficult to measure or mitigate but addressing inefficiencies and waste can reduce the impact. Visibility and quality checks during manufacturing help pinpoint defects so you can avoid spending time, money, and emissions on defective goods. If a recall occurs, track and-trace capabilities provide visibility into minimizing the impact and help you reduce emissions and waste in conducting broader-than-necessary recalls.

Put your ESG plan into action by connecting your supply chain to get the data needed to balance cost, service, and carbon footprint.

Transportation, which touches every supply chain ecosystem and stage of production, distribution, and returns, has accounted for about 25% of all GHG emissions. A highly accurate demand forecast further ahead of time provides the data needed to opt for slower transport modes with a lower carbon footprint when possible. E2open helps CPG companies convert the demand for finished goods into accurate transportation forecasts by mode and lane, then secure capacity with preferred carriers for the best rate and equipment with lower emissions. Your company’s brand loyalty requires that you are protected against instances of regulatory noncompliance and exposure to reputational risk. As you are onboarding suppliers, e2open helps ensure that suppliers meet your standards and operate within the code of conduct with respect to human rights, working conditions, and other risk factors. Automated screenings of transaction partners help ensure that you don’t work with sanctioned parties. Robust trade compliance strengthens your governance, and bolsters import and export compliance. Your ESG readiness – the ability to track and report impacts, reduce your company’s footprint, maintain an ethical supply chain, and meet compliance requirements – starts and ends with your connected supply chain.

Why e2open?

End-to-end visibility and control have long been key challenges to making better business decisions. While the supply chain itself is inherently connected, the processes are inherently siloed. This is due to disparate data sources and disconnected processes and systems across vast supply chain networks.

Enter the pandemic. In a relatively short period of time, we’ve witnessed unprecedented disruptions in demand, supply and logistics. What was a fairly free-flowing, demand-driven process, became restricted and supply constrained. Factory shutdowns. Supply disruptions.

E2open is a world-leading provider of networked, cloud-based supply chain technology and services focused on providing supply chain resiliency during supply and demand volatility.

The company’s connected supply chain platform and multi-enterprise networking technologies represent a unifying and composable system—a system giving you the ability to see, forecast, act, and advance in the most informed and intelligent manner, optimizing making, moving and selling across the entire value chain when certainty isn’t certain.

The combination of an integrated end-to-end platform, best-in-breed applications, and harmonized decision grade data from a holistic network of four ecosystems comprised of over 400,000 enterprises provide a single source for real-time insight and actionable information across the entire supply chain.

Connected processes and systems provide a secure connection to this decision-grade network data, empowering companies with the visibility and capability to optimize efficiencies and manage supply chain volatility in real time. All of this enables suppliers, manufacturers, transporters, and fulfillment channels across the supply chain to operate as one, optimizing supply, demand, and delivery efficiently and sustainably while the world we live in is in constant motion.

E2open — the value is in our name—an open supply chain ecosystem of record, from planning to execution to sales and fulfillment, providing you next level supply chain efficiencies and a roadmap to business transformation at a pace that is right for you.

E2open. The Connected Supply Chain. Moving as one. ™

Network

All ecosystems & tiers always connected trading partners

Data

Uniform decision grade harmonized, timely, and complete

Applications

Unified & intelligent holistic decision making

Process

Multi-tier & multi-enterprise end-to-end process orchestration

Network achitecture

Supply chains are complex. They are global. And they are outsourced to hundreds, if not thousands, of partners to make, move and sell goods around the world. Consider the hundreds, thousands, even millions of hand-offs testing the integrity of a company’s supply chain everyday—suppliers, manufacturers, transporters, and fulfillment channels.

While supply chains are connected in theory, oftentimes the processes and data for true connection are not. Organizations are often siloed, and supply chain technology purchases frequently follow this fragmentation. This lack of coordination creates the environment for disconnect and therein incomplete and inaccurate data and information. Time and again, the structural challenges of today’s supply chains lead to indecision or uninformed decision making. These hasty decisions and delayed responses often lead to inadequate business outcomes.

What if you had a single source for real-time insight and actionable information enabling automated response and better decision making across the entire value chain? What if you had a solution that brought together all aspects of the extended supply chain while addressing supply chain volatility, disruption, excess cost, and waste?

Imagine an open, end-to-end cloud-native platform, with best-in-breed supply chain applications, and harmonized, decision-grade data from the world’s largest multi enterprise network. A multi-tier network of suppliers, manufacturers, transporters, and fulfillment channels all connected through business processes and uniform data.

The following architecture visual represents the connected supply chain platform from e2open.

The largest network of interconnected partners

Clients oftentimes expand the capability of their supply chain technologies one point solution at a time. E2open embraces that mindset, but advocates for the progression to include complete connectedness through an open platform. The connected supply chain platform from e2open provides access to hundreds of thousands of trading partners across four ecosystems (demand, supply, global trade, and logistics).

The value of access is only as good as the data that is traded. Harmony® from e2open normalizes this vast amount of data into a single source of truth, guiding the supply chain through potential volatility.

Intelligent applications, informed through field proven AI, provide a unifying capability across the entire value chain— Channel, Planning, Global Trade, Logistics and Supply. All applications and data are exposed through a single pane providing visibility across the entire supply chain.

Key benefits

With e2open, CPG supply chain professionals gain better visibility, collaboration, and control supporting a connected supply chain, moving as one. Learn more at consumer packaged goods supply chain management.

Unified supply chain technology platform and interconnected partner network

Timely, accurate, and complete data establishing decision-grade information

Real-time decision-making capabilities and automated responses

Business transformation through a supply chain working together as one

Subscribe to receive e2open updates

Interested in learning more? Stay current with the latest e2open news – from company updates to thought-leadership pieces, and so much more!

Complete this form to subscribe to e2open updates.