Table of contents

- An industry confronting an onslaught of threats

- Food and beverage companies are facing a multitude of complex challenges

- Doing the right thing

- Volatile demand and supply

- Navigating logistics and border crossings

- Complex issues call for a more connected food and beverage supply chain

- What if you had a connected supply chain?

- Why e2open?

- Network architecture

- The largest network of interconnected partners

- Key benefits

Agile supply chain solutions for an industry facing fundamental shifts in how the world shops, buys, and consumes food and drink

Food and beverage makers are grappling with shifting consumer preferences, spiky demand, supply chain disruptions, raw materials pricing volatility, and much more—all while battling the competition and addressing environmental, social, and governance initiatives. Yesterday’s technology is not up to the challenge.

Food and beverage companies are facing a multitude of complex challenges

Maintaining customer service levels

Atypical demand and promotion history

Materials & packaging sourcing challenges

Supply constraints & margin erosion

Rapidly evolving trade regulations

Logistics demand and promotion history

End-to-end traceability

Achieving ESG objectives

Doing the right thing

In today’s environment, taking market share, growing revenue, and lowering costs are not enough. Consumers and boardrooms expect food and beverage companies to source ethically, be mindful of the planet, and act with integrity. In the supply chain, this requires looking beyond your four walls. Food and beverage supply chain leaders need to consider the actions and impacts of all their suppliers and partners across all ecosystems—upstream suppliers, downstream channels, logistics providers, and global trade partners. A daunting task to be sure, but it creates tremendous value and strong competitive differentiation.

100vw, 1266px” /><noscript><img width=)

Volatile demand and supply

Keeping the right product on the shelf at the right time has never been more challenging. Consumer expectations for convenience, sustainability, and low prices are evolving rapidly. Economic uncertainty, global conflicts, and ongoing pandemic and endemic fears are causing dramatic swings in demand. Meanwhile, supply-side challenges and disruptions continue to make it harder to establish and follow accurate long-term plans. Without connecting demand to supply and sensing actual versus plan, food and beverage makers will not survive for long.

100vw, 1187px” /><noscript><img width=)

Navigating logistics and border crossings

Recent events have shined a spotlight on the complexities of moving raw materials and finished products across the globe and to last-mile destinations. Global conflicts and trade wars mean rapidly evolving regulations and exposing companies to penalties for non-compliance. Furthermore, companies too easily leave money on the table by not understanding new and changing trade agreements. Food and beverage companies struggle to optimize logistics spend with fluctuations in logistics capacity and pricing driven by many of the same events impacting supply and demand. And once reliable shipment ETAs now require delicate logistics orchestration to detect potential delays and proactively address those with the greatest downstream impact.

100vw, 1266px” /><noscript><img width=)

Complex issues call for a more connected food and beverage supply chain

Structural challenges of today’s supply chains |

|

|---|---|

| NOT integrated | Disconnected processes, systems, applications and data |

| Poor data | Late, inaccurate and incomplete data leading to indecision |

| Siloed decisions | Misaligned priorities leading to disconnected and uninformed decision-making |

| Reactive | A series of hasty decisions and delayed responses resulting in poor outcomes |

The modern supply chain |

|

|---|---|

| Integrated | Unified supply chain technology platform and interconnected partner network |

| Harmonized | Timely, accurate, and complete data enabling decision grade insight and information |

| Connected decisions | Real-time decision-making capabilities and automated responses |

| Proactive | Business transformation and a supply chain working together as one |

What if you had a connected supply chain?

Achieve ESG objectives

Can you see the environmental impact of your suppliers’ suppliers?

Food and beverage companies increasingly recognize the importance of environmental, social, and corporate governance (ESG) objectives. Customers and investors demand it, governments require it, and a changing climate makes the consequences of inaction clearer each year. More than 90% of the ESG footprint is in the supply chain. That means the bulk of your footprint—including the impact of sourcing, processing, transportation, and distribution—is likely outside your direct control or ability to easily measure.

Proactively minimize ESG risk across your entire supply chain

The food and beverage industry is at the forefront of leading this charge. The good news is that decisions to lower ESG risk tend to positively impact the bottom line. And real impact starts with connections and data across all suppliers, customers, and partners. Add in actionable insights to proactively identify sources of opportunity and make informed decisions.

Start meeting ESG objectives

- Track and report ESG impacts using relevant data at every tier of supply, manufacturing, transportation, and distribution

- Source with confidence and optimize partner selection decisions

- Maintain compliance by screening every customer and supplier against worldwide denied party lists

- Make emissions-informed decisions at the point of booking to choose the optimal mode of transportation and route

End-to-end ESG system of record for your supply chain

the extended supply chain, including upstream suppliers, downstream distributors, and logistics partners and every step in between. End-to-end ESG is particularly elusive because the bulk of the footprint—especially Scope 3 GHG emissions—comes from outsourced third parties that are not under your direct control.

Many of the world’s biggest enterprises across various industries already use e2open’s network-based platform to successfully track cost and service metrics. The same core framework can also provide the foundation for an end-to-end ESG system of record for your supply chain.

Learn more at www.e2open.com/by-need/esg-for-supply-chain/

Holistic planning

Does your demand plan deal with constrained supply?

Planning for food and beverage supply chains requires accuracy, insight, and speed to support an industry with diverse, fast-moving, and perishable goods. Connectivity with customers is critical in predicting their needs, and connectivity with suppliers is critical in determining the ability to meet those needs.

Build resiliency into your demand plan

Transform traditional planning and meet corporate objectives. Plan collaboratively with internal and external stakeholders. Facilitate consensus by balancing demand, supply, and financial goals. Tap fresh data Global CPG company transforms business planning to deal with a more volatile supply chain and use proven machine learning algorithms to gain cross-functional buy-in, align internal teams and external partners, and evaluate the cost of tradeoffs.

Holistic planning realized

- Improve service levels and on-shelf availability

- Achieve consistently profitable, execution ready plans that balance demand, supply, and financial goals to facilitate consensus across internal and external stakeholders.

- Anticipate, understand, and shape demand with collaborative workflows, machine learning algorithms, and automation, powered by information from across all sales channels.

- Gain 30 to 40% in forecast accuracy by creating accurate near-term forecasts that reflect current market realities using real-time data, automation, and machine learning algorithms

Global CPG company transforms business planning to deal with a more volatile supply chain

With deep roots in agriculture, the company owned the category and grew steadily over time. However, changing consumer preferences started to erode market share, and while rising costs and regulatory pressure created additional challenges and risks. The company transformed its planning process to be more demand-driven and to better collaborate with its suppliers. As a result, inventory costs are down, service levels are up, and planning cycle time is now days instead of weeks.

Meet demand with agility

Does your demand plan survive contact with the real world?

“No demand plan survives first contact with the point of-sale system,” with apologies to Helmuth von Moltke. Demand forecasts and plans have always struggled with accuracy. Now, the deluge of global disruptive events has greatly exacerbated inaccuracy as historical data has become all but obsolete. Planning is and will always be an essential function of supply chains. Successful supply chains need to sense actual demand and supply and act with agility to ensure an optimal outcome.

Sense and respond to spiky demand and supply uncertainty

E2open helps some of the largest food and beverage companies in the world leverage vast and diverse data, supply chain networks, AI/ML, automation, and sensing capabilities to effectively plan and reconcile demand, supply, and inventory; and to constantly monitor, detect, and address real-world deviations from plan that threaten service and financial goals. On average, food and beverage companies have reduced forecast errors by 30 to 40 percent.

Meeting demand with agility realized

- Continuously monitor, detect, and address real-world deviations from plan

- Employ AI to assure supply continuity helps you get ahead of supply shortages and potential stockouts

- Optimize inventory targets for materials, ingredients, and finished products at all stocking locations

Global breakfast food company takes customer fill rates to the next level

By connecting forecasting and retailer data through e2open’s integrated planning and demand sensing capabilities, a global breakfast foods company was able to improve forecast accuracy by 47 percent in cereals and as much as 144 percent in other categories. Accurate daily forecasts based on current signals and visibility to store-level execution data allows the company to sense and respond to changes in fast-moving markets, better serve customers, and maximize performance of product introductions and events.

Optimized logistics

Is your logistics management system maximizing your spend?

Global supply chain disruptions don’t just impact supply and demand. The orchestration of logistics around the world or down the street has crippled supply chains. Port lockdowns and congestion, capacity shortages, and fluctuating freight rates are testing shippers and carriers alike. An optimized approach has the agility to deal with challenges through network data, end-to end visibility, and the application of AI/ML to detect issues while there is time to take corrective action.

Optimize transportation spend and gain in-transit visibility

Whether inbound or outbound, you need to identify capacity shortfalls, manage by exception, and ensure that the right carrier is hauling the right lane at a market competitive rate. An optimized logistics approach leverages network data to identify areas where carriers are experiencing issues and identifies the best course of action to avoid OTIF (on-time in-full) fines, detention costs, and increased carrier rates.

Optimized logistics realized

- Proactively manage capacity and ensure that the right carrier is hauling the right lane at a market competitive rate

- Transportation planning that lets you make choices that are most environmentally friendly as well as optimize cost and timing

- Streamlined direct-to-consumer fulfillment across town or across the globe

Sargento Reduces Freight Spend and Improves Visibility

Tasked with transporting over 24 million pounds of cheese each month, Sargento needed to eliminate manual shipment processing and gain control of transportation costs. This reputable cheese manufacturer chose to implement a flexible, scalable multimodal transportation management system (TMS) that would meet the company’s operational needs today and in the future. Using e2open’s Transportation Management application, Sargento can automate freight payments, reduce less-than-truckload (LTL) shipments and improve visibility and cost allocation.

Does your logistics team need a boost?

Managing logistics is not a core competency for every company, and it’s not always cost-effective to do it yourself. Let our 250+ logistics coordinators, analysts, managers, and supply chain engineers put the power of our transportation management solutions and four connected ecosystems to work for you, giving you more time for other strategic supply chain initiatives.

Learn more about e2open Logistics as a Service at www.e2open.com/by-need/logistics-as-a-service/

100vw, 1266px” /><noscript><img width=)

Compliant global trade

Are you complying with all the rapidly changing regulations?

Global trade is becoming increasingly complex and costly to manage. Food and beverage companies now source from and sell within more jurisdictions than ever, and trade regulations fluctuate with greater frequency. Understanding these changes in a timely manner is extremely challenging. And manually wrangling import and export rules means missed customs refunds and potentially higher duties and taxes.

Use a single solution for efficient global trade management

Minimize the manual effort for clearance and declarations and mitigate risk by managing all government trade compliance regulations in a single solution. Get all export and import reviews detailing required documentation for cross-border moves in and out of a country. E2open can also help maximize customs refunds and minimize duties and taxes.

Compliant global trade realized

- Ensure import compliance for every inbound shipment and collaborate with suppliers, brokers, carriers, and freight forwarders

- Navigate complex and evolving regulations to maximize customs refunds and minimize duties and taxes.

- Efficiently mitigate risk by accessing and managing clearance and declarations through a single solution

Global food manufacturer saves over $40 million in duty costs

A global food manufacturer and distributor was trying to manage its processes using mostly manual efforts, which resulted not only in duplicate efforts and inconsistencies across the organization but also a greater risk of non-compliance. The manufacturer turned to e2open to manage imports, exports and duties for a comprehensive approach involving leading global trade technology— including an automated free trade agreement (FTA) process. The results are substantially reduced duty costs and inventory levels while enhancing product availability for customers.

Why e2open?

End-to-end visibility and control have long been key challenges to making better business decisions. While the supply chain itself is inherently connected, the processes are inherently siloed. This is due to disparate data sources and disconnected processes and systems across vast supply chain networks.

Enter the pandemic. In a relatively short period of time, we’ve witnessed unprecedented disruptions in demand, supply and logistics. What was a fairly free-flowing, demand-driven process, became restricted and supply constrained. Factory shutdowns. Supply disruptions.

E2open is a world-leading provider of networked, cloud-based supply chain technology and services focused on providing supply chain resiliency during supply and demand volatility.

The company’s connected supply chain platform and multi-enterprise networking technologies represent a unifying and composable system—a system giving you the ability to see, forecast, act, and advance in the most informed and intelligent manner, optimizing making, moving and selling across the entire value chain when certainty isn’t certain.

The combination of an integrated end-to-end platform, best-in-breed applications, and harmonized decision grade data from a holistic network of four ecosystems comprised of over 400,000 enterprises provide a single source for real-time insight and actionable information across the entire supply chain.

Connected processes and systems provide a secure connection to this decision-grade network data, empowering companies with the visibility and capability to optimize efficiencies and manage supply chain volatility in real time. All of this enables suppliers, manufacturers, transporters, and fulfillment channels across the supply chain to operate as one, optimizing supply, demand, and delivery efficiently and sustainably while the world we live in is in constant motion.

E2open — the value is in our name—an open supply chain ecosystem of record, from planning to execution to sales and fulfillment, providing you next level supply chain efficiencies and a roadmap to business transformation at a pace that is right for you.

E2open. The Connected Supply Chain. Moving as one.™

Network

All ecosystems & tiers always connected trading partners

Data

Uniform decision grade harmonized, timely, and complete

Applications

Unified & intelligent holistic decision making

Process

Multi-tier & multi-enterprise end-to-end process orchestration

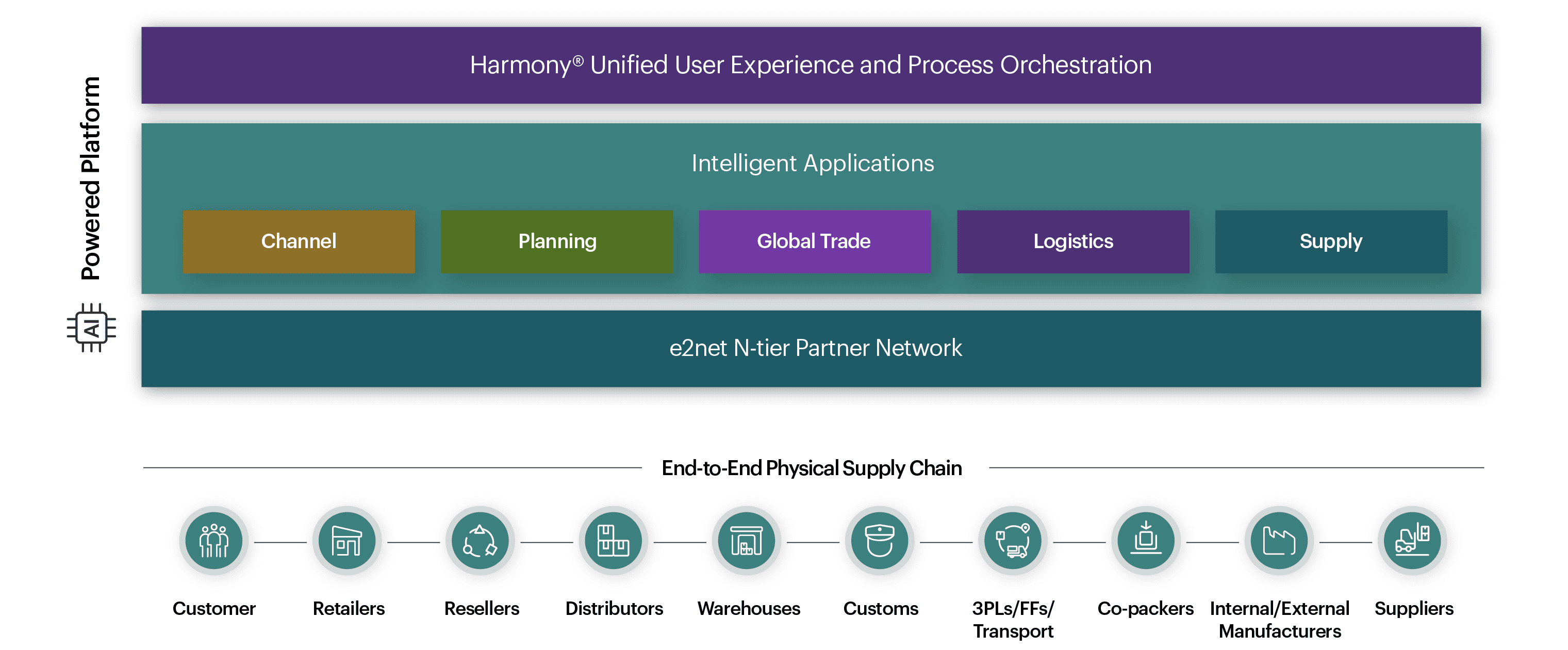

Network achitecture

Supply chains are complex. They are global. And they are outsourced to hundreds, if not thousands, of partners to make, move and sell goods around the world. Consider the hundreds, thousands, even millions of hand-offs testing the integrity of a company’s supply chain everyday—suppliers, manufacturers, transporters, and fulfillment channels.

While supply chains are connected in theory, oftentimes the processes and data for true connection are not. Organizations are often siloed, and supply chain technology purchases frequently follow this fragmentation. This lack of coordination creates the environment for disconnect and therein incomplete and inaccurate data and information. Time and again, the structural challenges of today’s supply chains lead to indecision or uninformed decision making. These hasty decisions and delayed responses often lead to inadequate business outcomes.

What if you had a single source for real-time insight and actionable information enabling automated response and better decision making across the entire value chain? What if you had a solution that brought together all aspects of the extended supply chain while addressing supply chain volatility, disruption, excess cost, and waste?

Imagine an open, end-to-end cloud-native platform, with best-in-breed supply chain applications, and harmonized, decision-grade data from the world’s largest multi enterprise network. A multi-tier network of suppliers, manufacturers, transporters, and fulfillment channels all connected through business processes and uniform data.

The following architecture visual represents the connected supply chain platform from e2open.

The largest network of interconnected partners

Clients oftentimes expand the capability of their supply chain technologies one point solution at a time. E2open embraces that mindset, but advocates for the progression to include complete connectedness through an open platform. The connected supply chain platform from e2open provides access to hundreds of thousands of trading partners across four ecosystems (demand, supply, global trade, and logistics).

The value of access is only as good as the data that is traded. Harmony® from e2open normalizes this vast amount of data into a single source of truth, guiding the supply chain through potential volatility.

Intelligent applications, informed through field proven AI, provide a unifying capability across the entire value chain— Channel, Planning, Global Trade, Logistics and Supply. All applications and data are exposed through a single pane providing visibility across the entire supply chain.

Key benefits

With e2open, supply chain professionals gain better visibility, collaboration, and control supporting a connected supply chain, Moving as one.™ Learn more at consumer packaged goods supply chain management.

Unified supply chain technology platform and interconnected partner network

Timely, accurate, and complete data establishing decision-grade information

Real-time decision-making capabilities and automated responses

Business transformation through a supply chain working together as one

Subscribe to receive e2open updates

Interested in learning more? Stay current with the latest e2open news – from company updates to thought-leadership pieces, and so much more!

Complete this form to subscribe to e2open updates.