Supply Collaboration: The Difference Between Supply Shortages and Revenue Wins

Outsourced manufacturing creates blind spots that lead to lost inventory and missed revenue. Connected planning and multi-tier collaboration turn that risk into a competitive edge.

Read our latest brief, Harness the Power of Sub-Tier Collaboration, to discover how.

Missing components could mean missing revenue

If you can’t build it, you can’t sell it. Tech companies often lack insight to inventory and forecasts for critical components, leading to product misses, obsolete inventory, and reduced profitability.

ANALYST REPORT

Nucleus Research: Assessing the Value of e2open Supply Chain Planning for Manufacturers

Download this independent analyst report to see how our integrated software platform helped two large manufacturers successfully manage several production challenges at once and resulted in $15M in total savings through inventory optimization, enhanced visibility, and improved supplier collaboration.

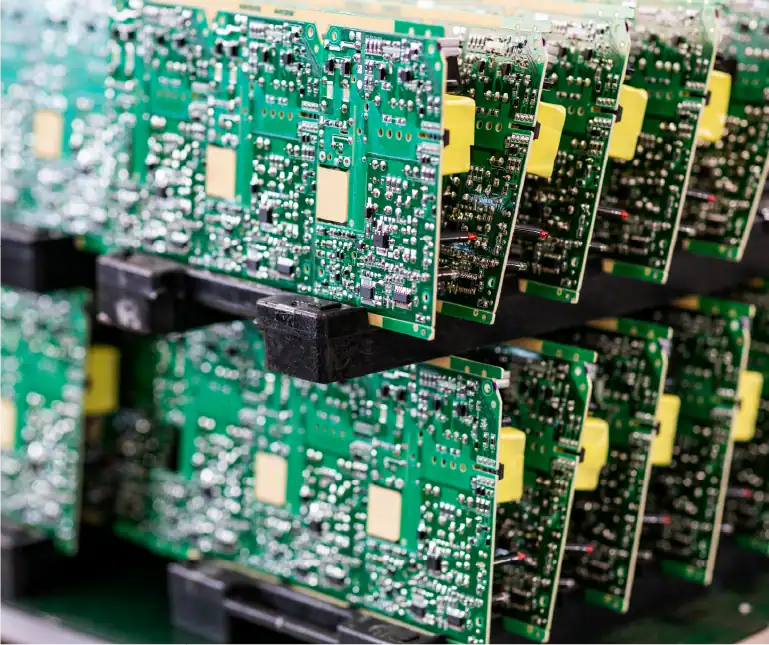

REDUCE BLIND SPOTS

Make production more predictable with supply collaboration

The more components and materials your product has, the more blind spots you have to deal with. The solution is synchronized supply chain planning, which gives you X-ray vision into sub-tier inventories and forecasts across outsourced manufacturing and suppliers.

OUR PARTNERS

High-tech manufacturers rely on e2open

Connected forecasts and supplier collaboration give you an edge over the competition

E2open is the pioneer of supply planning and collaboration solutions for the high-tech industry

E2OPEN AT WORK

See how e2open is transforming supply chains

BUSINESS OUTCOMES

The benefits of alignment:

Putting planning and supply on the same path

1-3 Charles A. Brennan, “Assessing the value of e2open SCP for manufacturers,” Nucleus Research, January 2025