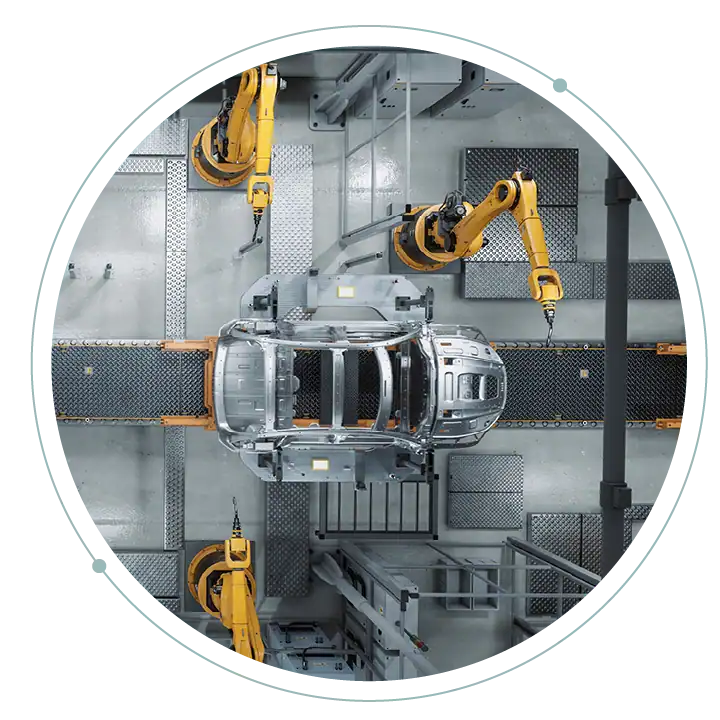

Supply chain disruptions hit automotive manufacturers hard. One missing semiconductor chip or aluminum shortage can shut down entire production lines, resulting in lost revenue and frustrated customers.

Today’s automotive supply chains face constant volatility from unexpected demand surges, natural disasters, and geopolitical tensions. The question isn’t whether disruptions will happen—it’s how quickly you can respond when they do.

Why automotive supply shortages keep getting worse

Modern automotive manufacturing depends on complex, multi-tier supplier networks. When disruptions strike, they create ripple effects that spread faster than you can track them.

Sudden demand spikes overwhelming supplier capacity

Severe weather events disrupting plant operations

Global instability and labor disputes delaying critical components

Misaligned inventory across your extended network