Key takeaways

- What is supply chain planning (SCP)? SCP is the process of aligning supply and demand through coordinated demand forecasting, production and logistics planning.

- Why is SCP valuable to organizations? The value of SCP lies in reducing costs, improving customer satisfaction, boosting efficiency, supporting smarter decisions and increasing agility.

- How does effective planning improve supply chain performance? It enables proactive scenario modeling, real-time adjustments and operational flexibility, even under uncertainty.

- What are common mistakes companies make with SCP initiatives? Common pitfalls include treating SCP as only an IT project and neglecting change management or strategic buy-in.

- What modern trends are reshaping SCP’s impact? AI-driven insights, collaborative tools, resilience and risk management, sustainability metrics and integrated planning functions are changing how SCP delivers value.

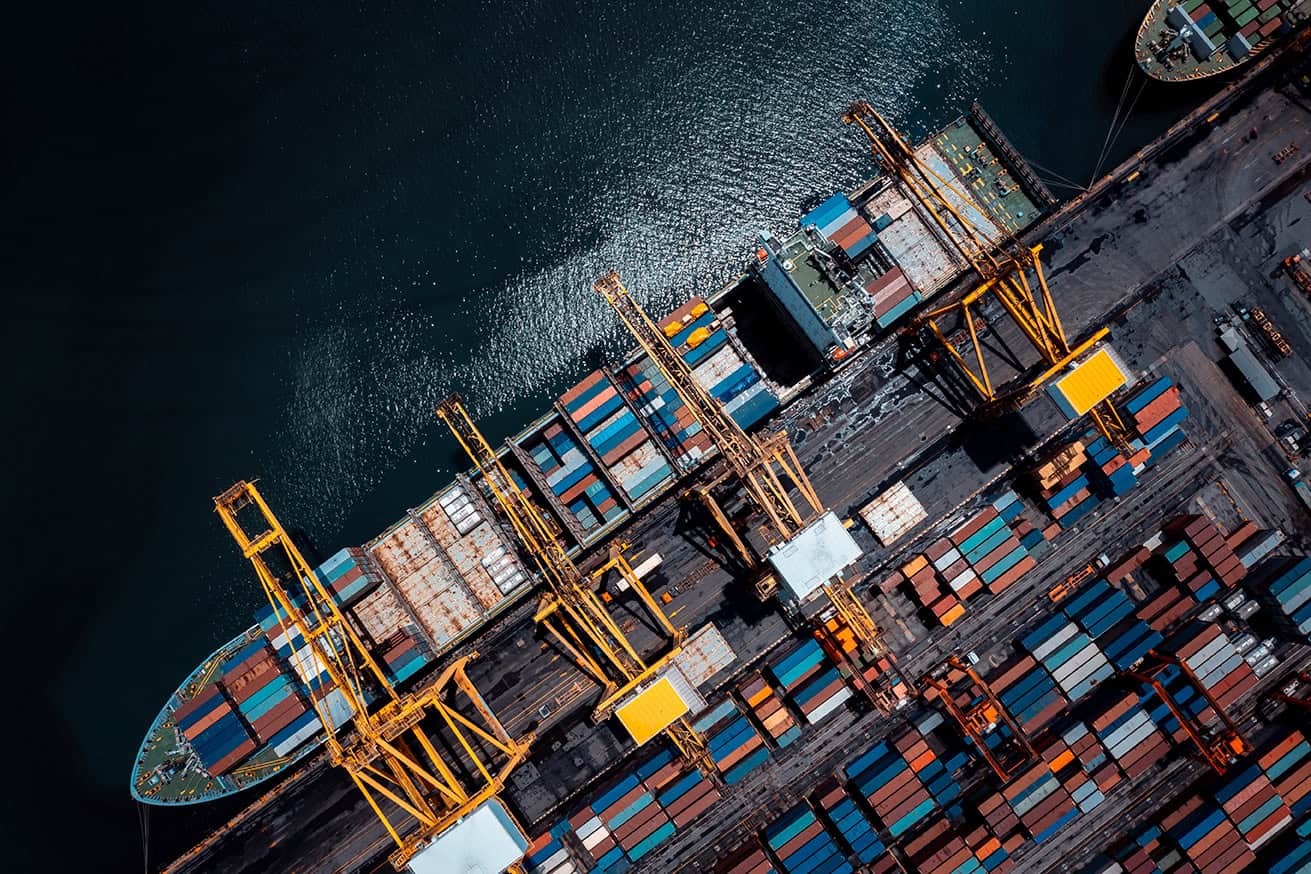

The backbone of modern supply chains

Supply chains are under constant pressure to deliver more with less; less time, less waste, less risk. Without a strong planning process, companies often end up with mismatched resources, excess inventory in some places and shortages in others. The result is higher costs, dissatisfied customers, and a lack of predictability.

Supply chain planning (SCP) solves this by aligning supply with demand across the entire network. It’s the discipline that connects forecasting, production, distribution and logistics into one coordinated strategy. Effective planning ensures the right products are made, moved and delivered at the right time.

The building blocks of strong planning

Demand planning

This is where everything begins. By forecasting customer demand using historical data, market insights and predictive analytics, companies can anticipate what products will be needed, when, and in what quantities. Accurate demand planning prevents both costly overstocks and frustrating shortages.

Production and manufacturing scheduling

Once demand is forecasted, production planning ensures resources are allocated efficiently. This includes scheduling manufacturing runs, aligning labor and equipment capacity, and securing raw materials. Good scheduling keeps factories productive without overburdening them.

Distribution and replenishment planning

Finished goods must be positioned where they’re needed most. Replenishment planning determines how inventory flows through the network; whether to central hubs, regional warehouses or directly to retailers. The goal is to minimize transport costs and lead times while keeping shelves stocked.

Integration into S&OP or IBP

The most effective planning doesn’t happen in isolation. Sales & Operations Planning (S&OP) and Integrated Business Planning (IBP) bring together finance, sales, operations and supply chain teams to align on one unified plan. This integration ensures demand forecasts and supply strategies connect with business objectives, creating accountability and cross-functional visibility.

How planning translates into real-world value

Together, those building blocks form a resilient foundation. When they operate in sync, SCP delivers benefits across the business:

- Cost reduction: By minimizing excess inventory, reducing transportation inefficiencies and cutting waste in production, SCP lowers operating expenses. For example, better forecasting reduces unnecessary safety stock, freeing up capital for more strategic investments.

- Customer satisfaction: Reliable product availability and on-time delivery directly improve customer experience. Planning ensures that products are in the right place at the right time, strengthening loyalty and reducing lost sales due to stockouts.

- Efficiency gains: Coordinated scheduling and distribution eliminate redundant work and reduce bottlenecks. This streamlining allows companies to use labor, equipment and materials more productively, ultimately improving throughput.

- Better decision-making: With real-time data and scenario modeling, supply chain leaders can test the impact of different strategies before committing. This empowers decision-makers to choose the path that balances cost, service and risk most effectively.

- Risk mitigation and agility: Planning provides built-in resilience by identifying potential risks early and preparing alternative strategies. Whether it’s rerouting shipments, sourcing from backup suppliers or scaling production up or down, SCP equips businesses to pivot quickly under pressure.

From forecasts to fast responses: SCP at work

SCP is more than balancing spreadsheets. It’s what allows companies to shift from theoretical forecasts to practical, real-time responses when conditions change. A strong plan builds resilience by creating both precision and flexibility, predicting demand as accurately as possible while preparing the network to adapt when disruptions inevitably arise.

From chaos to control: A real-world example of SCP in action

Here’s how one global manufacturer used e2open’s supply chain planning capabilities to turn disruption into a competitive advantage.

A global mining and construction vehicle maker was struggling to keep production running and machines in the field. In this industry, one broken machine can stop operations, cost millions in lost productivity, and throw off entire schedules. Unpredictable swings in supply and demand meant suppliers sat on excess capacity during downturns and ran short when business picked up, making it difficult for the manufacturer to source crucial repair parts and keep machines running.

The company’s supply base included more than 6,000 suppliers spread across multiple tiers. Teams spent hours chasing updates by phone and email, trying to confirm commitments and track down critical components. Without clear visibility into supplier capacity, production plans fell apart when conditions shifted. Delays cascaded through the supply chain, hurting on-time deliveries and dealer service.

To get ahead of these problems, the manufacturer turned to e2open for an integrated supply chain platform. Using e2open’s supply planning application, the manufacturer could upload forecasts and instantly share them with thousands of suppliers. Multi-tier suppliers, in turn, provided capacity and inventory data back through the same system, giving planners a clear view of constraints. With this visibility, planners used e2open to allocate scarce parts across factories and product lines, adjust build schedules, and maximize available production resources.

They also implemented e2open’s logistics control tower capabilities to connect suppliers, freight forwarders, and carriers across all transport modes. This gave them predictive ETAs down to the item level, so plant managers, dealers, and customers knew exactly when machines or replacement parts would arrive.

With the platform in place, the results were tangible. With forecast, capacity, and shipment data all visible in one place, planners no longer had to spend hours tracking down information. Scarce parts could be allocated days or weeks earlier than before, keeping high-priority builds on schedule. Predictive ETAs let dealers plan around deliveries and reduce costly downtime in the field. These improvements cut delays, improved service reliability, and made the supply chain far more resilient to demand swings.

Forecasting + planning: Stronger together

A forecast, no matter how accurate, is useless if the supply chain can’t execute against it. Companies that rely only on demand projections often overcommit, misallocate resources, or fail to meet customer expectations when supply constraints aren’t considered.

Likewise, even the best planning processes crumble without reliable demand signals. If the forecast is inaccurate, production schedules, replenishment plans, and distribution routes end up mismatched to actual customer needs, leading to excess stock in some places and shortages in others.

When forecasting and planning work together, companies unlock agility and accuracy. Forecasts feed into planning processes, ensuring production and distribution decisions reflect real demand. Planning, in turn, shapes how forecasts are used, grounding them in operational realities like supplier capacity and logistics constraints. The result is a virtuous cycle: more accurate forecasts improve planning, and smarter planning refines forecasting.

Why supply chain planning projects fail (and how to avoid it)

Supply chain planning is a powerful capability for teams to have at their fingertips, but many initiatives fall short of expectations. Avoiding common pitfalls can make the difference between stalled progress and long-term success.

Mistake 1: Treating SCP as (solely) a technology project

Many organizations assume that buying new planning software is the solution in and of itself. But without aligning processes and people, even the best tool won’t deliver results.

How to avoid it: Position planning as a strategic business capability, not just an IT system. Technology should support a clear vision and operating model.

Mistake 2: Overlooking change management

Shifting to more advanced planning capabilities requires teams to adopt new ways of working, from using forecasts in daily decisions to collaborating across departments. Resistance to change can derail adoption.

How to avoid it: Invest in training, communication and leadership sponsorship. Create champions within teams who can reinforce adoption and demonstrate quick wins.

Mistake 3: Failing to secure stakeholder alignment

Supply chain planning touches multiple functions, including sales, operations, finance, and procurement. Without alignment, each team may pursue its own objectives, undermining the overall plan.

How to avoid it: Build cross-functional governance early. Use S&OP or IBP frameworks to unify goals and create accountability.

Mistake 4: Implementing without strategic clarity

Rushing to deploy tools without defining KPIs, objectives, and roadmaps often leads to misaligned expectations and limited value.

How to avoid it: Start with the end in mind. Define success metrics, prioritize quick wins, and map a phased adoption plan that scales as the organization matures.

The future of planning: Smarter, faster, greener

Supply chain planning is evolving rapidly. New technologies and priorities are reshaping how organizations forecast demand, allocate resources and manage risk. Four trends stand out:

AI and analytics

Artificial intelligence and advanced analytics are transforming how supply chains forecast and plan. Instead of relying only on historical data, AI taps into real-time signals like market shifts, customer behavior, and even weather forecasts to create more accurate demand predictions. Smarter forecasting reduces errors, minimizes excess stock, and supports data-driven decisions across the enterprise.

Real-time data integration

Speed is critical in today’s volatile environment. Real-time planning capabilities allow companies to sense disruptions, evaluate scenarios, and adjust quickly. By connecting planning systems directly to execution data, businesses gain the agility to pivot without losing momentum.

Resilience and risk management

Disruptions are inevitable, but their impact can be reduced. Modern supply chain planning emphasizes resilience by diversifying suppliers and sourcing regions, maintaining backup suppliers, and embedding risk assessments into planning cycles. These practices help companies absorb shocks and maintain service levels when conditions change.

Sustainability metrics

Sustainability has shifted from a “nice-to-have” to a core planning requirement. Modern SCP incorporates carbon emissions, energy usage, and ethical sourcing into decision-making alongside cost and service metrics. This dual focus ensures companies remain competitive while meeting stakeholder expectations for responsible operations.

Turn planning into performance with e2open

Supply chain planning delivers the greatest impact when supported by the right technology. Manual processes and disconnected tools can only take you so far. To unlock true operational excellence, you need real-time visibility, advanced analytics, and an integrated platform that connects every part of your supply chain.

That’s where e2open comes in. With a unified planning and execution platform, e2open helps businesses:

- Align demand forecasts with supply strategies

- Optimize production and inventory across global networks

- Respond faster to disruptions with real-time data and insights

- Improve collaboration with suppliers, partners and internal teams

A Nucleus Research report on supply chain planning for manufacturers found that companies using e2open cut operational costs by up to 35%, improved service levels by 17% and boosted productivity by 15%, including one automotive manufacturer that saved $15M by optimizing inventory, supplier collaboration and production planning.

Discover how e2open helps build resilient, connected supply chains →