Nucleus Research study reveals how manufacturers achieve measurable ROI with automated supply chain planning solutions.

Manufacturing supply chain challenges: The cost of manual planning

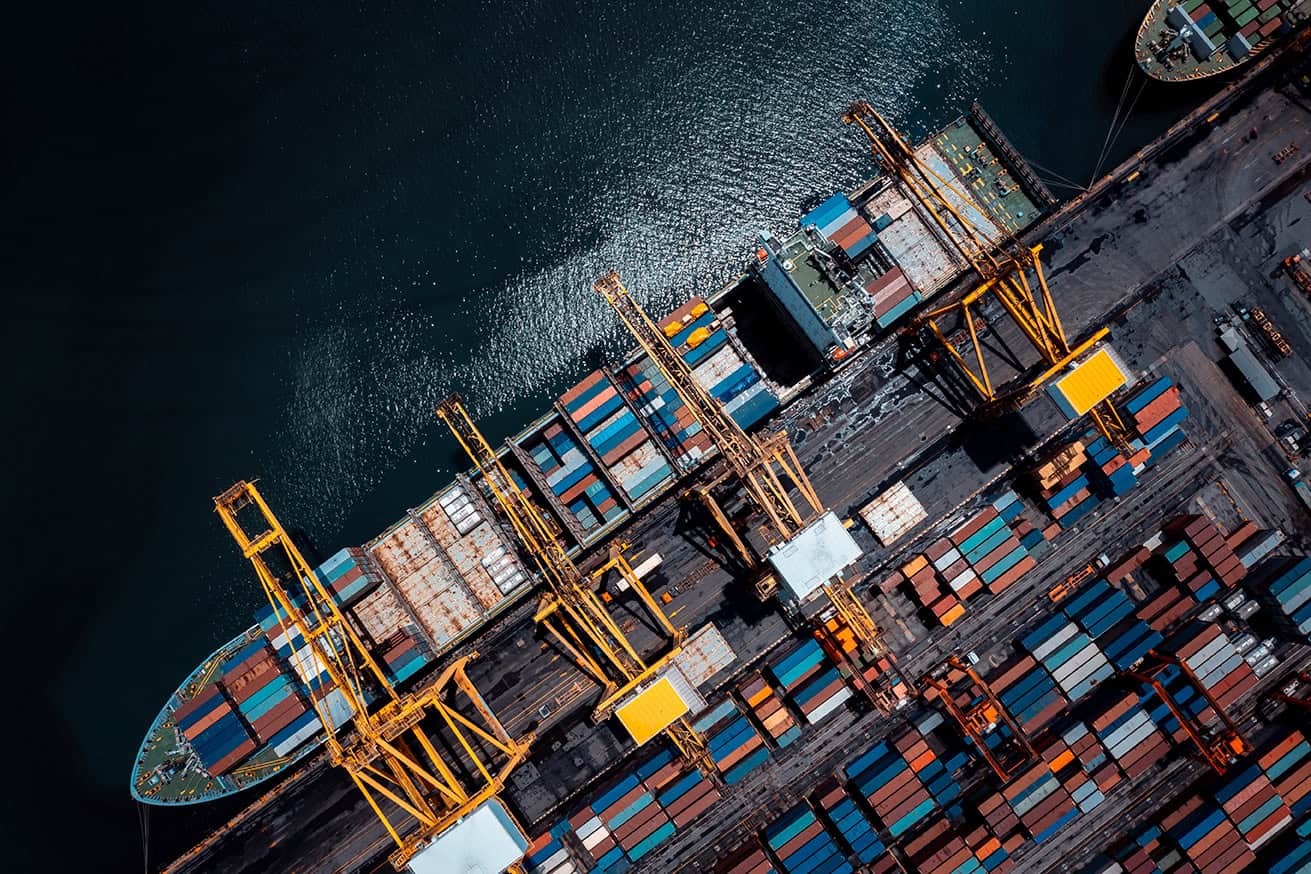

The factory’s humming, but the clock on delivery is brutal. Brackets are stuck in Shanghai, held up by a sub-supplier in Mexico, aluminum’s running short, and your ops manager is still tallying parts by hand. Meanwhile, competitors slash costs with their investments in real-time visibility while you’re stuck in your spreadsheets and sticky notes. Another contract slips away.

For manufacturers, the messy reality of supply chains means you need to adapt fast. Today’s manufacturing leaders face unprecedented challenges:

- Raw material shortages

- Manual planning processes

- Limited supplier visibility

- Strong global competition

- Rising operational costs

In this blog post, we’ll show how e2open’s applications bring clarity and control to the planning chaos. From forecasting demand with AI, to keeping inventory in the sweet spot, to turning supplier blind spots into collaboration, these tools are built for the real-world problems manufacturers face every day.

When manufacturing gets messy, supply chain planning software helps bring order

This Nucleus Research report delivers analyst-backed results that hit home for manufacturing executives. Manufacturers using e2open supply chain planning solutions receive real business outcomes in speed, savings, and operational stability, including:

- 5-35% lower operational costs through smarter inventory optimization

- 17% higher service levels with better visibility and real-time tracking

- 15% more productivity thanks to automated workflows

The takeaway? Hard work isn’t enough. Winning in today’s manufacturing environment now takes data-driven planning, automation, and a new playbook for integrated supply chain visibility.

Manufacturing planning solutions

Smarter demand forecasts with demand planning

Challenge: Forecasting demand with outdated and manual processes.

Solution: AI-powered demand planning with real-time market data gives manufacturers a sharper view of what’s coming. So, you can plan with confidence instead of relying on guesswork.

Application: Demand Planning — where manufacturing forecasting gets real.

Optimized inventory, fewer headaches

Challenge: Overflowing shelves or last-minute scrambles for missing materials.

Solution: Supply chain planning software keeps stock in the sweet spot—saving warehouse space, reducing carrying costs, and eliminating stockouts.

Application: Multi-echelon Inventory Optimization — your optimal stock zone.

Clearer supplier visibility and collaboration

Challenge: Supplier blind spots that create production disruptions.

Solution: Real-time insights help manufacturers spot risks sooner, sync faster, and turn supplier chaos into strategic collaboration.

Application: e2net — a spotlight on your supplier base.

Production planning without the guesswork

Challenge: Capacity planning and resource allocation.

Solution: Know your capacity, efficiently align resources, and keep production moving. Supply chain planning software coordinates every part, person, and process before work begins.

Planning Application Suite—the powerhouse behind manufacturing production planning.

Cut costs, boost supplier efficiency

Challenge: Spreadsheet chaos and manual workflow bottlenecks.

Solution: With automated workflows and clear supplier visibility, manufacturing operations run leaner and smarter.

Supply Application Suite—the heavyweight for streamlined manufacturing operations.

Real-time signals for demand sensing

Challenge: Relying on outdated data for critical planning decisions.

Solution: Demand sensing pulls in real-time signals—from sales data to shipments to weather patterns—and runs them through machine learning models built for rapid response. The result? Forecasts that actually keep up with your manufacturing reality so you can cut forecast errors, reduce safety stock and pivot production in days instead of months.

Demand Sensing Suite—the intelligent signals for smarter manufacturing planning.

Supply chain planning in the real world: Manufacturing case studies

If you’ve made it this far through the blog, we’re sure you’re beginning to wonder how supply chain planning software might apply to your company. Let’s look at a pair of real-world before-and-after case studies highlighted by Nucleus Research. Two manufacturers, two outcomes: an automaker saved $15M, and a $40B equipment maker cut aged inventory by 30%—both with e2open supply chain planning.

Global automotive manufacturer: $15M saved with e2open

This global automaker runs a massive network of 16,000 Tier 1 and 5,000 aftermarket suppliers. But with planning mostly managed manually, supply chain visibility was limited, and disruptions hit hard. The 2021 semiconductor crisis exposed critical gaps in their planning capabilities.

After reviewing vendors, they chose e2open for its manufacturing expertise and integrated capabilities. The results are impressive:

- $15M in savings through smarter inventory optimization

- Global logistics visibility to track shipments in real time

- Better supplier collaboration to spot issues early and adjust production before disruptions hit

- Optimized planning to build more profitable model mixes and improve stability

What was once a reactive and fragmented approach is now a connected, resilient manufacturing supply chain.

End-to-end visibility that delivers measurable results for an equipment manufacturer

A $40B equipment manufacturer was weighed down by fragmented planning and weak inventory control. With no end-to-end visibility, costs were rising, and performance was slipping. By deploying e2open’s integrated supply chain platform, the company turned things around:

- 30% reduction in aged inventory

- 88% to 95% improvement in On-time in-full (OTIF) delivery

- 20% reduction in planner headcount

- Complete end-to-end visibility and streamlined planning processes

What had been a patchwork of inefficiencies became a streamlined, data-driven manufacturing operation with measurable ROI.

Get the report, see the results

Fragile networks. Supplier blind spots. Planning processes that feel stuck in another decade. Sound familiar? You’re not the only one running into the same brick wall.

Get the Nucleus Research report to learn how e2open helps manufacturers cut costs, boost service levels, and build supply chains that actually keep up.

FAQ

What is supply chain planning software for manufacturing?

Manufacturing supply chain planning software integrates demand forecasting, inventory optimization, production scheduling, and supplier collaboration into a unified platform. It replaces manual spreadsheet-based planning with automated, data-driven processes that improve efficiency and reduce costs.

How much does manufacturing planning software cost?

Investment varies based on company size and complexity, but manufacturers typically see ROI within 12-18 months through inventory optimization, reduced operational costs, and improved service levels. The Nucleus Research study documents savings ranging from $15M for large manufacturers to 30% inventory reductions for equipment manufacturers.

What’s the difference between ERP and supply chain planning software?

While ERP systems manage transactional data, manufacturing supply chain planning software provides advanced analytics, AI-powered forecasting, and optimization capabilities. It works alongside ERP to transform historical data into actionable insights for future planning decisions.

How long does supply chain planning software implementation take for manufacturing companies?

Typical implementations range from 6-12 months depending on complexity and integration requirements. Most manufacturers see initial benefits within 3-6 months as key modules come online, with full ROI realized within the first year.

Can supply chain planning software integrate with existing manufacturing systems?

Yes, modern manufacturing planning platforms integrate seamlessly with ERP systems, MES, WMS, and other manufacturing software. APIs and pre-built connectors ensure data flows smoothly between systems without disrupting existing operations.