Industry

Supply Chain Software Solutions for Oil and Gas

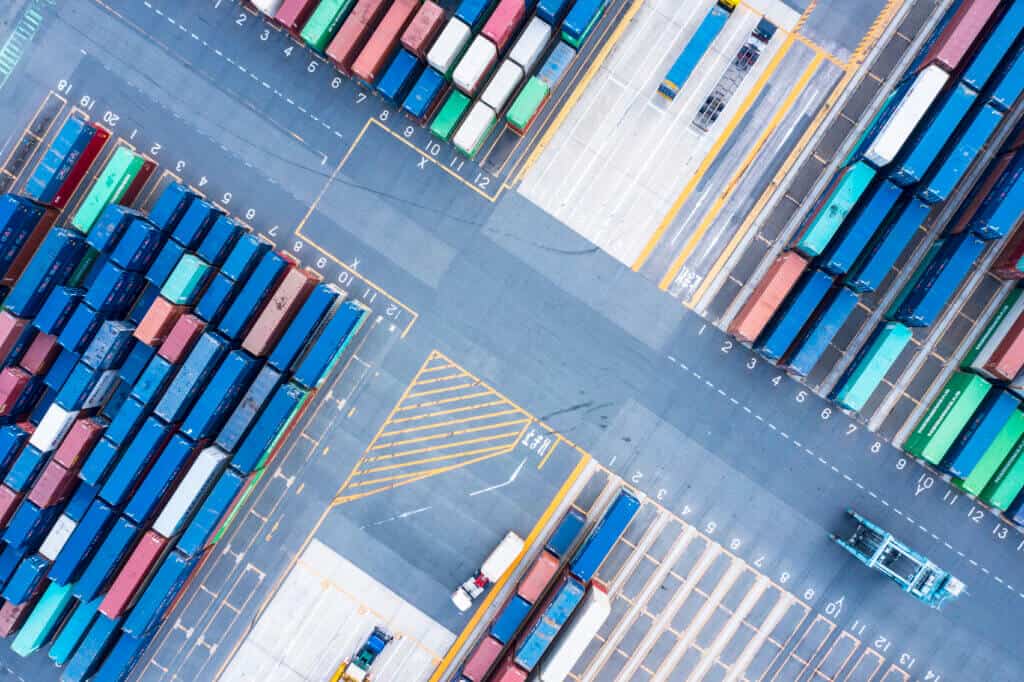

Supply constraints, logistics challenges, and global trade regulations drive the need for supply chain resiliency

The oil, gas, and chemicals industries experience the same supply constraints and logistics challenges that plague so many industries today. Shortages for oil and gas include long delays for drill pipes, which slow down drilling, and casings needed to prevent negative environmental impacts. One missing component can stop delivery on meeting customer commitments and put contracts at risk. Logistics impacts on the chemical industry include shortages of rail cars, truck capacity, and high ‘less-than-truckload’ (LTL) costs. Regulations for shipping and exporting oil and gas and chemicals products create complexities, such as managing the business rules for each product type with impacts on global trade, routes, mixtures, and costs. E2open is helping optimize supply chains dealing with constrained supply, logistics complexities, and global trade compliance to minimize risk.

Webinar On Demand

Making informed decisions in a supply-constrained world

Learn how companies can make more informed supply and inventory allocation decisions despite ongoing shortages of components, and raw materials.

2023 Gartner® Report

Magic Quadrant™ for Transportation Management Systems (TMS)

Gartner names e2open a leader. E2open’s Transportation Management System (TMS) can help companies manage the most complex use cases that are more commonplace today.

Index

E2open Ocean Shipping Index

E2open’s Ocean Shipping Index examines current trends based on real data related to several critical trade lanes and offers a historical context for even deeper insights. Decision-makers can use the index to understand the impact of disruptions, gain unique visibility into supply chain movements worldwide and take informed action based on actual data.

“One of our challenges had been managing the huge amount of transactional and planning data in order to make really effective and timely supply chain decisions. Now, we can crunch big data to get to key value opportunities. This has been a core element of our Integrated Business Value program.”

– Shell

Create a connected supply chain to take on supply and raw material shortages, and optimize transport and export challenges that slow or stop the flow of the oil, gas, and chemicals business.

A Chemical TMS preferred partner

Featured solutions for Oil, Gas, and Chemicals

Build a supply chain that keeps your business flowing