AI-Based Supply Signal Analyses Help Improve Supply Assurance Amid Uncertainty

E2open Supply Sensing uses real-time signals, artificial intelligence (AI), and market volatilities to predict supply shortages, so you can deliver better service and lower inventory costs.

Easily predict supply chain shortages and act decisively

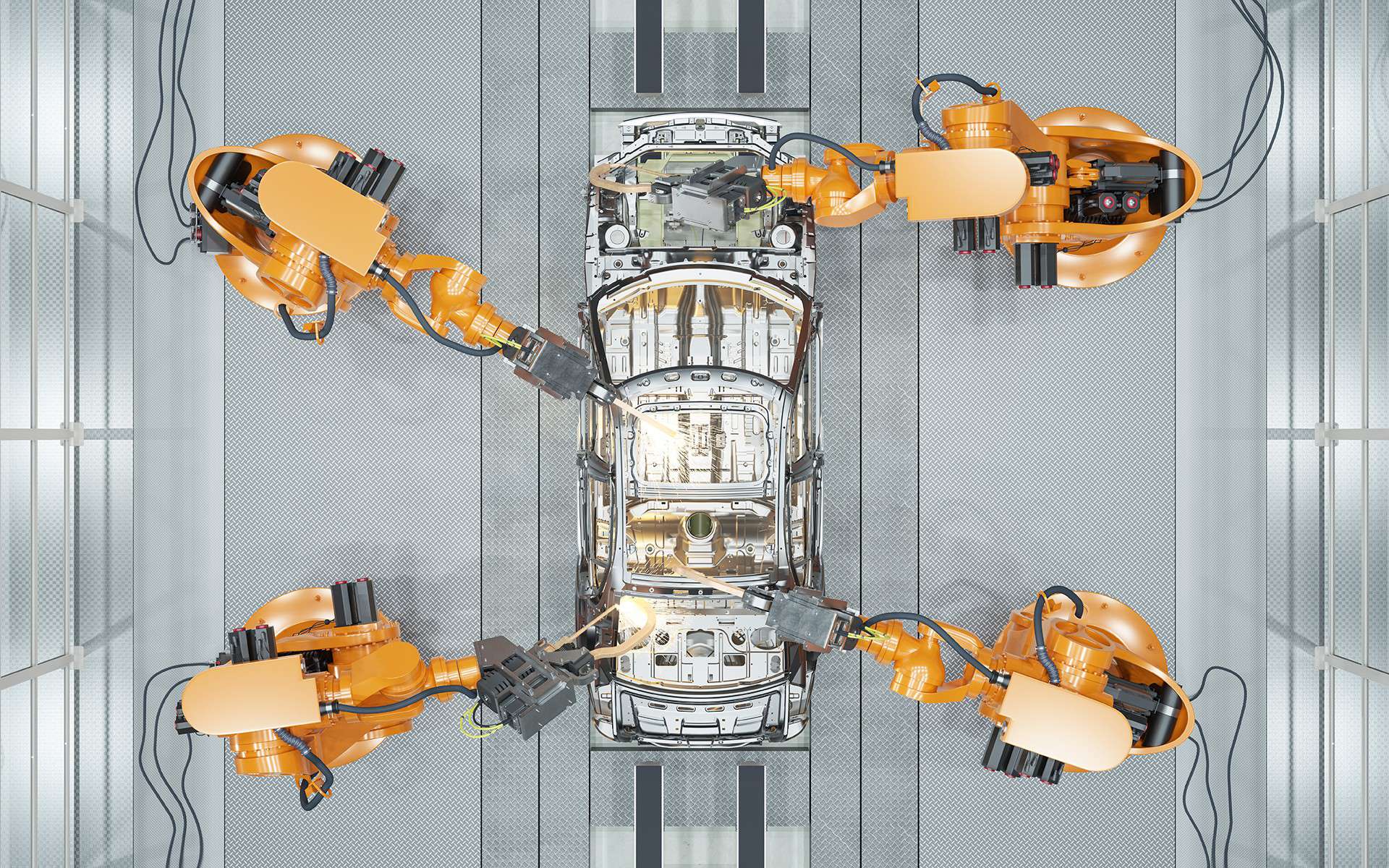

Uncertainty is the new norm

Factory closures, labor shortages, and container delays have become all too frequent today. It seems like constant change is the only constant. That makes predicting supply shortages more difficult than ever, putting organizations in a constant reactive state and leaving many of their customers unsatisfied.

Predict, react, and adapt when supply shortages hit

Use real-time data, artificial intelligence, and lead time variances to predict supply shortages and deliver better service.

Understand the risk of shortages

Real-time data and predictive analytics provide visibility into potential inventory shortfalls during specific periods.

Triage shortages for optimal outcomes

Prescriptive analytics give you options such as selecting alternate suppliers, adding manufacturing runs and changing production volumes.

Safeguard service levels

The ability to monitor the current service risk at any level of aggregation based on the state of demand and supply helps you keep customers happy.

Balance inventory and service risk

You can review tradeoffs for the current service risk versus the cost of inventory at any stage to help maximize profits—even during a holiday season.

Resolve the most pressing risks

By identifying and responding to only the most critical near-term service risks, you save time, maintain customer loyalty, and minimize the cost of expedites.

Mitigate risk from end to end

Assuring supply helps you mitigate risk, including internal operations, upstream contract manufacturers, and downstream distribution partners.

Increased visibility

For more accurate decisions

More confidence

With collaborative planning

Fewer costly expedites

By making smarter AI-driven decisions

Related applications

Customers

Testimonials

Take the guesswork out of supply risks.